Fuel cells, integral components of hydrogen fuel cell electric vehicles(FCEVs), serve as eco-friendly energy conversion systems that generate electric power and heat through the chemical reaction of hydrogen and oxygen. Korean local governments are enthusiastic about investing in relevant equipment to expand the FCEV market, but they often face opposition from local residents. To alleviate citizens’ concerns, it is necessary to establish infrastructure that can ensure both the productivity and safety of hydrogen fuel cells.

The Korea Research Institute of Standards and Science has developed a technology for real-time detection of micro defects on the fuel cell surface during the production process.

The newly developed technology is based on deep learning and enables real-time 3D measurement. It can detect defects on the surface shape in a single shot, allowing continuous monitoring of product quality without interrupting the manufacturing process.

A single-shot pattern projection method is employed for the real-time 3D measurement of the surface shape. The light with dense composite grid pattern is projected onto the surface of an object, and then the deformed pattern upon reflection is analyzed to obtain 3D information about defects or damages.

However, one limitation of this methodology is that it cannot measure surfaces with low reflectivity or various mixed patterns. For instance, the metal separator, which is a core component of fuel cells, is challenging to be inspected using real-time 3D measurement because it is made of stainless steel (SUS) with an uneven surface.

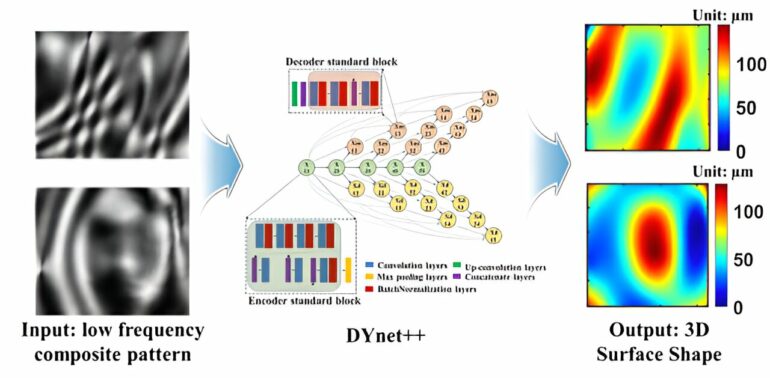

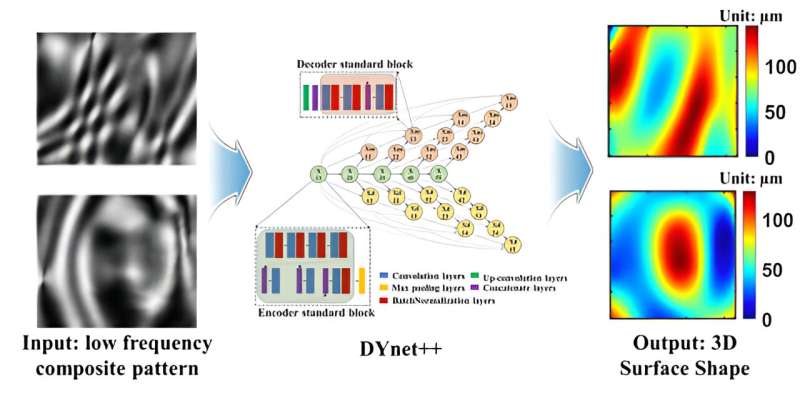

The 3D shapes predicted by the trained DYnet++ network. © Korea Research Institute of Standards and Science (KRISS)

To overcome this limitation, the Optical Imaging and Metrology Team of KRISS introduced an artificial intelligence (AI) algorithm to the pattern projection method. They used DYnet++, a new deep learning network developed by KRISS, which was trained with measurement data on thousands of surface shapes. This allows DYnet++ to perform real-time 3D morphology measurements of surfaces with low reflectivity or complex shapes.

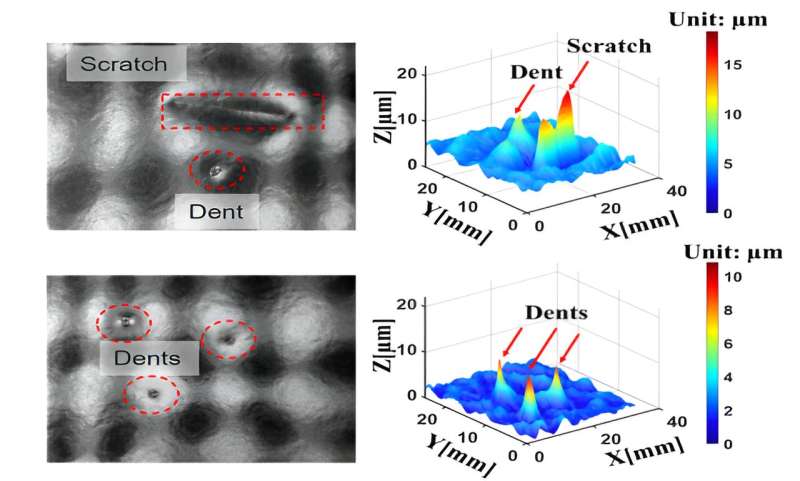

To apply this technology to fuel cell samples, the research team further trained the AI algorithm using data on metal separators with surface defects. The 3D morphology measurement results shows that dents and scratches on the sample surfaces, which are difficult to be determined through conventional 2D inspection, are successfully detected in a single shot because the AI algorithm acquired the application capabilities even with a small amount of data.

Thousands of image data with arbitrary complex patterns and their corresponding 3D shapes are acquired and used to train the designed DYnet++ network. Transfer learning is employed for the analysis of data obtained under the new environmental conditions, which requires only one-tenth of the amount of data to modify the trained model compared to what was used to build the initial algorithm. Based on the modified model, the 3D measurement results for various complex patterns can be predicted.

The technology developed through this research can be easily applied to the production line, regardless of the shape or size of the subject to be measured. It enables automatic inspection of defects even during a manufacturing process with external vibrations and significant temperature changes. This technology can contribute to the introduction of smart factories in various areas of the manufacturing industry, including fuel cells, by increasing productivity, improving product quality, and reducing costs.

Measurement results of a fuel cell sample with a rough surface and low reflectivity. © Korea Research Institute of Standards and Science (KRISS)

Dr. Young-Sik Ghim, the leader of the Optical Imaging and Metrology Team, stated, “This technology can be used for real-time inspection of various faults and defects in fuel cell metal separators. It can not only maximize performance but also improve the durability and safety of the fuel cells that are currently being produced.”

The paper is published in the journal IEEE Transactions on Industrial Electronics.

More information:

Manh The Nguyen et al, DYnet++: A Deep Learning Based Single-Shot Phase-Measuring Deflectometry for the 3-D Measurement of Complex Free-Form Surfaces, IEEE Transactions on Industrial Electronics (2023). DOI: 10.1109/TIE.2023.3253940

Provided by

National Research Council of Science & Technology

Citation:

Real-time inspection of defects on fuel cell surface by artificial intelligence (2023, September 26)