Lithium-ion batteries are a widely used class of rechargeable batteries in today’s world. One of the processes that can hamper the functioning of these batteries is an internal short circuit caused by direct contact between the cathode and anode (the conductors that complete the circuit within a battery).

To avoid this, separators composed of polyolefins—a type of polymer—can be employed to maintain separation. However, these separators can melt at higher temperatures, and the inadequate absorption of electrolytes (essential for conveying charges between electrodes) can result in short circuits and diminished efficiency. To tackle these issues, several different methods have been proposed.

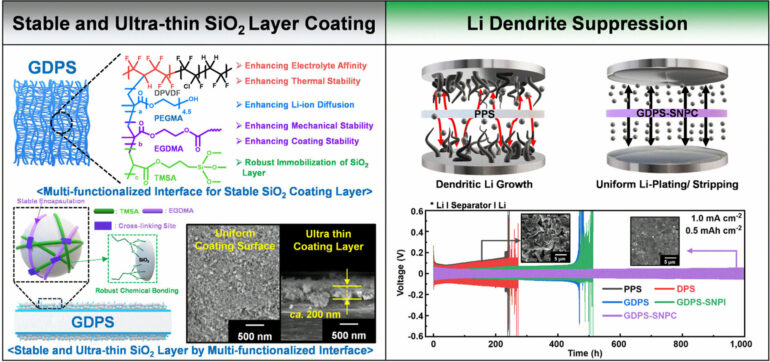

One such method is to apply ceramic coatings on the separators to improve the way they handle pressure and heat. However, this can increase the thickness of the separators, reduce their adhesion, and harm battery performance. Another technique is to use polymer coatings, in a process known as graft polymerization. This involves the attachment of individual units (monomers) to the separators to give them the desired qualities.

A recent study published in Energy Storage Materials now demonstrates successful graft polymerization on a polypropylene (PP) separator, incorporating a uniform layer of silicon dioxide (SiO2). The discovery is the result of a joint study that including Assistant Professor Jeongsik Yun from the Department of Energy and Chemical Engineering at Incheon National University.

Dr. Yun was motivated by the need for high-performance battery materials in electric vehicles to achieve longer driving ranges, an area he has been actively working on. Beyond improving battery performance, his goal is to ease consumer concerns about battery explosions, potentially influencing their decisions to embrace electric vehicles.

According to him, “Battery explosions are frequently initiated from the melting of a separator. The commercial battery separator is made of polyolefins, a class of polymers which are vulnerable to heat. We therefore aimed to improve the thermal stability of the commercial separators by coating them with thermally robust materials such as SiO2 particles.”

In this study, a PP separator was modified in several ways. Initially, it was coated with a layer of polyvinylidene fluoride, a chemical chosen to enhance electrolyte affinity and thermal stability, while also introducing grafting reaction sites. Then, the separator underwent grafting with methacrylate molecules, followed by a final coating with SiO2 particles. These modifications made the separator stronger and more resistant to heat, suppressed the growth of lithium dendrites, and helped improve the cycling performance.

The modifications not only preserved the energy storage of Li-ion batteries per unit volume, but also outperformed other coating methods in cell performance. This technique thus shows promise for creating robust separators and advancing the use of lithium-ion batteries in electric vehicles and energy storage systems.

“We hope that the results of this study can enable the development of high-safety lithium batteries. We believe that the thermal stability of these batteries will greatly benefit the current fire-sensitive electric vehicle field. In the long term, this can motivate people to choose electric vehicles and in urban areas, reduce the suffering of people from breathing in the polluted air generated by the internal combustion engines,” envisions Dr. Yun.

In summary, this study presents a reliable method for creating an innovative and durable separator for lithium-ion batteries, potentially paving the way for a greener future.

More information:

Jaewon Park et al, Ultra-thin SiO2 nanoparticle layered separators by a surface multi-functionalization strategy for Li-metal batteries: Highly enhanced Li-dendrite resistance and thermal properties, Energy Storage Materials (2023). DOI: 10.1016/j.ensm.2023.103135

Provided by

Incheon National University

Citation:

Researchers enhance safety of lithium batteries with graft polymerization technique (2024, January 25)