John Dolbow, professor of mechanical engineering and materials science at Duke University and Oscar Lopez-Pamies, professor of civil and environmental engineering at the University of Illinois at Urbana-Champaign, have collaborated on computational fracture mechanics to understand better and predict material failure. Their work has been published in the Journal of the Mechanics and Physics of Solids.

At the heart of their research is the hope of correcting an age-old formula used to test the strength of brittle material with important implications in construction, manufacturing and even medical applications. Decades ago, the Brazilian test was created to measure the breaking point of brittle materials, but its history is rooted in an impossible task.

Fernando L.L.B. “Lobo” Carneiro

(1913–2001) founded the Brazilian test quite literally at a crossroads. In Rio de Janeiro in the mid-20th century, a community needed to move a church standing at an important intersection. And if they couldn’t figure out how, the baroque building would have to be demolished. Carneiro was charged with engineering a solution to this massive operation, and to avoid the church’s destruction, he proposed putting concrete rollers underneath it so that they could move the church by rolling it to its new location.

But first, the rollers needed to be tested.

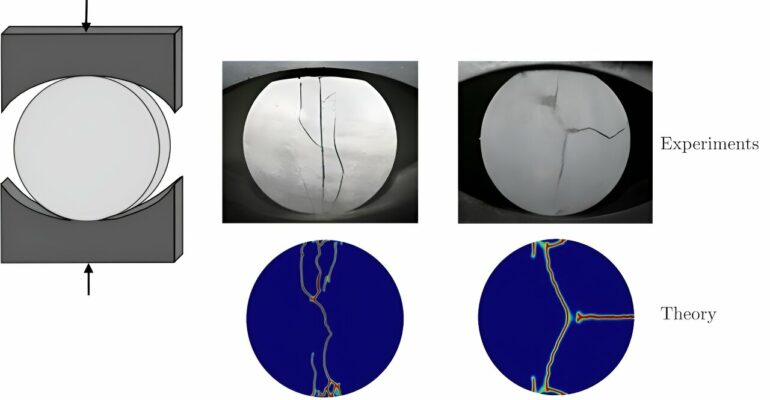

While testing concrete disks in compression, Carneiro observed that as the loads increased, the disks had a tendency to split into two pieces right down the middle. He quickly understood what was happening; although the disks were being compressed vertically, they were also being placed in tension in the horizontal direction.

Because concrete is relatively weak in tension compared to compression, this mode of failure was triggered first. Carneiro had accidentally discovered a simple way to indirectly measure the tensile strength of materials like concrete, such as rocks. Thus was born the “Brazilian test,” a standard test for brittle materials that has been in use since Carneiro first introduced it in 1943.

The test uses two stiff plates to compress a disk of material until it fractures, and it is widely employed due to the ease of specimen preparation and the application of the loads.

Over the past few decades, the test has also been the subject of a great deal of debate. The elegant formula Carneiro introduced to extract the strength from the peak force recorded in the test has been modified by ASTM International, for example. Some researchers have also suggested that the test simply isn’t valid unless failure starts right in the middle of the specimen, as opposed to near the plates where the loads are applied.

All of this is due to a misunderstanding of how materials fail and the interplay between strength and the sudden appearance of cracks, at least according to recent research that seeks to correct the formula at the heart of Carneiro’s method.

“Our species has been trying to understand fracture for a long time,” Lopez-Pamies said. “When things are subjected to sufficiently large amounts of force, eventually they break, right? It has implications in everything that has to do with solids.”

According to Lopez-Pamies, the Brazilian test is the poster child that illustrates what people have thought about fracture for what feels like forever. The test “has very significant misconceptions that researchers still apply, but they are going to get the wrong conclusions because its premise is incorrect.”

Dolbow and Lopez-Pamies identify a fundamental issue with the traditional understanding of material strength and the sudden appearance of cracks, emphasizing the need for a theoretical framework that accurately describes these phenomena. They argue that the misconceptions arise when there is only a focus on tension when stresses are applied and fracture occurs, which is really just one scalar.

“If you were able to monitor the forces or the stresses in the system, that alone won’t tell you when the cracks appear,” Lopez-Pamies explained. “So there are misconceptions about a single dimension versus multiple dimensions as it pertains to the Brazilian test.” The mechanical functions of this method also have implications in fields that collaborate closely with engineering, like medicine.

Dolbow brings up lithotripsy as an example. The medical procedure is used by doctors to break up kidney stones and informs much of the direction of their research into material failure. He says this procedure is important in understanding the framework of their research as fracture is the desired outcome in this case.

“We work with a particular material in our lab called BegoStone because its mechanical properties are so close to kidney stones,” he explained.

They ultimately came to realize the misunderstandings behind the Brazilian test while using it to try and measure the tensile strength of their BegoStone samples.

The results simply didn’t make sense with other measurements, so they began to question the assumptions behind the test itself. What they discovered pretty quickly was that the combined state of compression and tension actually mattered, and this fact has been overlooked for decades. Carneiro’s formula “is pretty close, but in some cases, the errors can be significant,” Dolbow said.

What their research proposes is a simple modification to the formula that could lead to more accurate assessments of material properties, influencing how materials are selected and used in construction, manufacturing and medical procedures. Importantly, the modification allows the test to be valid, independently of whether cracks start in the middle of the specimen or near the plates where the loads are applied.

What’s more, Dolbow and Lopez-Pamies suggest a potential paradigm shift in how researchers and practitioners measure tensile strength and predict material failure. This shift could pave the way for advancements in fracture mechanics theory and its application across different industries, but it ultimately underscores the need for innovative ideas in engineering practices that challenge the status quo.

More information:

Aditya Kumar et al, The strength of the Brazilian fracture test, Journal of the Mechanics and Physics of Solids (2023). DOI: 10.1016/j.jmps.2023.105473

Citation:

Researchers find new dimensions in decades-old strength test (2024, March 19)