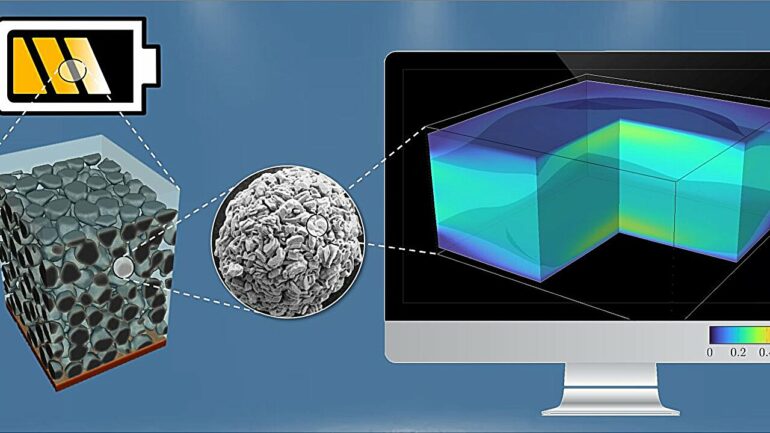

Which factors determine how quickly a battery can be charged? This and other questions are studied by researchers of Karlsruhe Institute of Technology (KIT) with the help of computer-based simulations.

Microstructural models help to discover and investigate new electrode materials. When sodium-nickel-manganese oxide is used as cathode material in sodium-ion batteries, simulations reveal modifications of the crystal structure during charging. These modifications lead to an elastic deformation, as a result of which capacity decreases.

The study is published in npj Computational Materials.

Research into new battery materials is aimed at optimizing their performance and lifetime and at reducing costs. Work is also underway to reduce the consumption of rare elements, such as lithium and cobalt, as well as toxic constituents.

Sodium-ion batteries are considered very promising in this respect. They are based on principles similar to those of lithium-ion batteries, but can be produced from raw materials that are widely accessible in Europe. And they are suitable for both stationary and mobile applications.

“Layered oxides, such as sodium-nickel-manganese oxides, are highly promising cathode materials,” says Dr. Simon Daubner, Group Leader at the Institute for Applied Materials–Microstructure Modeling and Simulation (IAM-MMS) of KIT and corresponding author of the study. Within the POLiS (stands for Post Lithium Storage) Cluster of Excellence, he investigates sodium-ion technology.

Fast charging creates mechanical stress

However, cathode materials of this type have a problem: Sodium-nickel-manganese oxides change their crystal structure depending on how much sodium is stored. If the material is charged slowly, everything proceeds in a well-ordered way.

“Sodium leaves the material layer by layer, just like cars leaving a carpark story by story,” Daubner explains. “But when charging is quick, sodium is extracted from all sides.” This results in mechanical stress that may damage the material permanently.

Researchers from the Institute of Nanotechnology (INT) and IAM-MMS of KIT, together with scientists from Ulm University and the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW), recently carried out simulations to clarify the situation.

Experiments confirm simulation results

“Computer models can describe various length scales, from the arrangement of atoms in electrode materials to their microstructure to the cell as the functional unit of any battery,” Daubner says. To study the NaXNi1/3Mn2/3O2 layered oxide, microstructured models were combined with slow charge and discharge experiments.

The material was found to exhibit several degradation mechanisms causing a loss of capacity. For this reason, it is not yet suited for commercial applications.

A change in the crystal structure results in an elastic deformation. The crystal shrinks, which may cause cracking and capacity reduction. INT and IAM-MMS simulations show that this mechanical influence decisively determines the time needed for charging the material. Experimental studies at ZSW confirm these results.

The findings of the study can be transferred partly to other layered oxides. “Now, we understand basic processes and can work on the development of battery materials that are long-lasting and can be charged as quickly as possible,” Daubner summarizes. This could lead to the widespread use of sodium-ion batteries in five to ten years’ time.

More information:

Simon Daubner et al, Combined study of phase transitions in the P2-type NaXNi1/3Mn2/3O2 cathode material: experimental, ab-initio and multiphase-field results, npj Computational Materials (2024). DOI: 10.1038/s41524-024-01258-x

Provided by

Karlsruhe Institute of Technology

Citation:

Researchers use microstructural modeling to optimize electrode materials for batteries (2024, May 21)