The number of collaborative mobile robots introduced in real-world settings is gradually increasing, with approximately 20,000 new installations per year. For their use to increase further, however, roboticists should ensure that these robots are both efficient and safe to use around humans.

Researchers at Skolkovo Institute of Science and Technology (Skoltech) have recently created CoHaptics, a system that merges collaborative robotics and haptics technology to improve the safety of human-robot collaboration. This system, presented in a paper pre-published on arXiv, can track human users’ movements using hand-tracking technology and provide tactile feedback to warn them about potential collisions with robots.

“Collaborative robots are designed to be safe for humans and are equipped with force/torques sensors,” Dzmitry Tsetserukou, associate professor, head of the Intelligent Space Robotics Laboratory, told TechXplore. “However, they typically only stop moving after a collision with objects is detected, which means that they can still be dangerous for sensitive parts of body, such as a user’s fingers, wrist, neck and head. This is one of the reasons why they are not widely used for human-robot collaborative tasks, but merely replace industrial robots in some specific tasks, such as palletizing, quality inspection, assembly, etc.”

In recent years, the use of robots has become particularly widespread in the industry and service sectors. To enhance their safety and efficiency, however, roboticists should devise collaboration techniques that consider both the dexterity that humans are capable of and the strength or power of robots.

“For example, if you work in an assembly line, where the elements to assemble products are heavy or different small parts are used, one collaborative robot can support you in picking up the heavy pieces and bring you close to the place to assemble the parts,” Miguel Altamirano Cabrera, Ph.D. student involved in the development of CoHaptics, told TechXplore. “However, the robot is working together with you, and some collisions can occur when your body interferes in the robot’s path.”

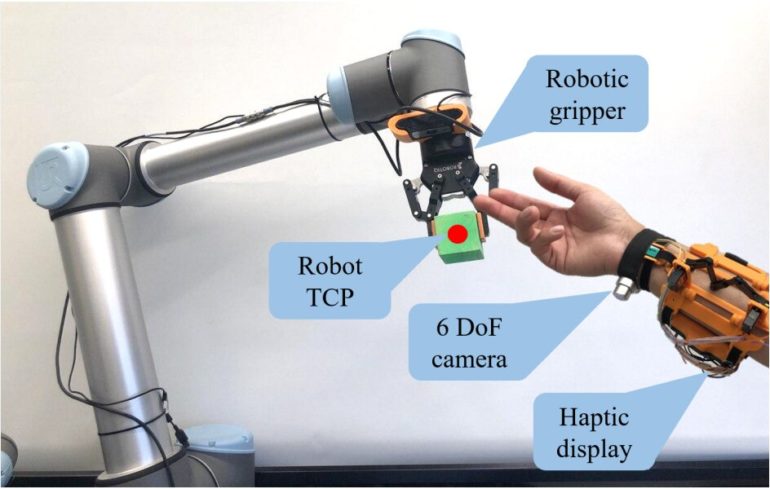

To reduce collisions between robots and humans, Tsetserukou, Altamirano Cabrera and their colleagues used a tracking system based on a 6 DoF camera that can be worn by users on their wrist. This camera collects data that can be used by the robot to infer the location of human workers in its proximity and avoid collisions with them.

To evaluate their system, Tsetserukou, Altamirano Cabrera and their colleagues carried out an initial experiment, where a human and a robot completed tasks within a shared environment. In this experiment, they also compared the time it took to complete tasks when the human user was using their haptic feedback-based system to the operation time when the user was not using the system.

The researchers found that, in instances where the robotic system was aware of a user’s position, their system reduced collisions with the robot and increased the safety of the human-robot interaction. However, the robot took longer to complete its mission, mainly because it deviated from its path in order to avoid collisions with the user.

“To solve this issue, we also provided the users with a ‘warning sign’ when it is close to the robot, warning them about potential collisions,” Altamirano Cabrera “This sign was given by haptic stimulation on their forearm by a sliding touching point, representing the robot’s distance.”

In addition to adapting a robot’s path to reduce collisions with humans, the researchers thus added a haptic feature to their system that informs human users about possible future collisions with robots in advance. Their assumption was that while working on an assembly line or in industrial settings humans might be so focused on the tasks at hand that they might not be paying attention to nearby robots.

“Luckily, we have a sense of touch, so this is the channel through which we decided to convey the risk of collision to humans,” Tsetserukou said. “We developed a haptic display dubbed RecyGlide that generates tactile stimuli in accordance with the distance between hand of a human and hand of a robot. When humans experience tactile feedback, they can move their hand to avoid collisions with the robot.”

In their system evaluations, the researchers found that users responded to the haptic feedback provided by their system within an average time of 0.32 sec, which is fast enough to prevent a possible collision. To increase the safety of robot-human collaboration further, they also developed an algorithm called haptic potential field.

The haptic potential field algorithm was designed to change the trajectory of a robot in a way that prevents it from colliding with humans, without interrupting its mission and hence continuing to move towards a target object. Through this algorithm, the CoHaptics system can use the information collected by the 6DoF camera worn by users on their wrist to modify the path of robots and prevent collisions.

“Our results showed that the information provided to the users by haptic stimulation increased the human-robot distance by 4.1 cm (from 12.39 to 16.55), and the robot’s path was reduced by 81%,” Altamirano Cabrera said. “From these results, we can conclude that the implementation of haptic stimulation to inform the users about their distance to the robot in a collaborative task could increase the safety of the users,”

In the future, CoHaptics could prove to be a highly valuable system for increasing the safety of workers working alongside mobile robots in industrial settings. Meanwhile, Tsetserukou, Altamirano Cabrera and their colleagues plan to devise new approaches that could further enhance human-robot collaboration.

As part of their current work, the team is working on building a 3D environment, dubbed Coverse (collaborative universe), which represents a factory where robots and workers can be tracked and animated in real-time. They could eventually also create similar representations for urban environments or other settings where robots might be deployed.

“The 3D representation we are creating appears in a gradient scale from green (safe) to red (hazard),” Tsetserukou said. “When part of the human body is in the proximity of a robot, the nearby user receives touch feedback, to avoid the potential injury. This 3D collaborative universe will potentially make the factory and city environment populated with humans and robots safer and more natural. One can imagine the scenario when you will receive haptic feedback when outdoor delivery robot is approaching you from blind zone. On the top of that, users could experience the location of the parcel transported by mobile robot right on their skin in real-time with a delivery haptic radar to meet the rover on time.”

An autonomous system that can reach charge mobile robots without interrupting their missions

More information:

Miguel Altamirano Cabrera et al, CoHaptics: Development of human-robot collaborative system with forearm-worn haptic display to increase safety in future factories. arXiv:2109.05912v1 [cs.RO], arxiv.org/abs/2109.05912

2021 Science X Network

Citation:

CoHaptics: A wearable haptic robot with a 6DoF camera to enhance the safety of human-robot collaboration (2021, October 28)

retrieved 28 October 2021

from https://techxplore.com/news/2021-10-cohaptics-wearable-haptic-robot-6dof.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.