An artificial intelligence algorithm can allow researchers to more efficiently use 3D printing to manufacture intricate structures.

The Washington State University study, published in the journal Advanced Materials Technologies, could allow for more seamless use of 3D printing for complex designs in everything from artificial organs to flexible electronics and wearable biosensors. As part of the study, the algorithm learned to identify, and then print, the best versions of kidney and prostate organ models, printing out 60 continually improving versions.

“You can optimize the results, saving time, cost and labor,” said Kaiyan Qiu, co-corresponding author on the paper and Berry Assistant Professor in the WSU School of Mechanical and Materials Engineering.

The use of 3D printing has been growing in recent years, allowing industrial engineers to quickly convert customized designs on a computer to a wide range of products—including wearable devices, batteries and aerospace parts.

But for engineers, trying to develop the correct settings for their printing projects is cumbersome and inefficient. Engineers have to decide on materials, the printer configuration and the dispensing pressure of the nozzle, for instance—all of which affect the final product.

“The sheer number of potential combinations is overwhelming, and each trial costs time and money,” said Jana Doppa, co-corresponding author and Huie-Rogers Endowed Chair Associate Professor of Computer Science at WSU.

Qiu has done research for several years in developing complex, lifelike 3D-printed models of human organs. They can be used, for instance, in training surgeons or evaluating implant devices, but the models have to include the mechanical and physical properties of the real-life organ, including veins, arteries, channels and other detailed structures.

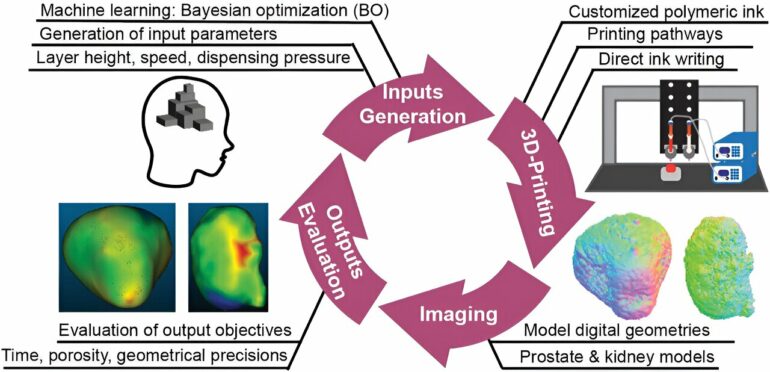

Qiu, Doppa, and their students used an AI technique called Bayesian Optimization to train and find the optimized 3D-printing settings. Once it was trained, the researchers were able to optimize three different objectives for their organ models—the geometry precision of the model, its weight or how porous it is and the printing time. Porosity of the organ model is important for surgery practice, for instance, because the model’s mechanical properties can change depending on its density.

“It’s hard to balance all the objectives, but we were able to strike a favorable balance and achieve the best possible printing of a quality object, regardless of the printing type or material shape,” said co-first author Eric Chen, a WSU visiting student working in Qiu’s group in the School of Mechanical and Materials Engineering.

Alaleh Ahmadian, co-first author and WSU graduate student in the School of Electrical Engineering and Computer Science, added that the researchers were able to look at all the objectives in a balanced manner for favorable results and that the project benefited from its interdisciplinary perspective.

“It is very rewarding to work on interdisciplinary research by performing physical lab experiments to create real world impact,” she said.

The researchers first trained the computer program to print out a surgical rehearsal model of a prostate. Because the algorithm is broadly generalizable, they could easily change it with small tunings to print out a kidney model.

“That means that this method can be used to manufacture other more complicated biomedical devices, and even [be extended] to other fields,” said Qiu.

More information:

Eric S. Chen et al, Machine Learning Enabled Design and Optimization for 3D‐Printing of High‐Fidelity Presurgical Organ Models, Advanced Materials Technologies (2024). DOI: 10.1002/admt.202400037

Provided by

Washington State University

Citation:

Self-improving AI method increases 3D-printing efficiency (2024, August 22)