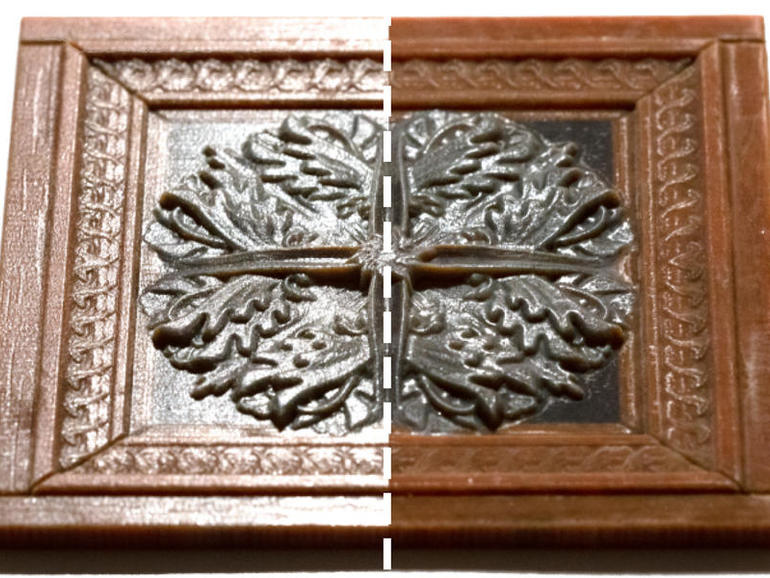

MIT: “In this image, the left side shows traditional 3D printing, which doesn’t have varying reflectivity. The right side shows the new improvements, where one can choose which surfaces are glossy and which are matte.”

Image courtesy of the researchers

The two most common desktop-style 3D printers are FDM (for fused deposition modeling) and SLA (or stereo lithography). FDM printers lay down layer after layer of filament, resulting in objects that have 3D printing’s trademark layer lines. SLA printers use resin and light to produce prints that are often without lines and highly detailed. But neither method is particularly adept at producing shiny objects.

That’s not to say traditional 3D prints can’t result in shiny objects. YouTuber “Uncle Jessy” post-processes large 3D prints to produce cosplay masks that have that Iron Man shine. He uses a combination of chemical treatments, old-fashioned sanding, primer, and painting techniques to get the look he seeks.

Also: ZDNet’s DIY-IT 3D Printing and Desktop Fabrication Discovery series

And let’s not forget the incredibly ill-advised and dangerous acetone vapor technique used to smooth ABS 3D prints. The idea is you set a small amount of acetone inside a closed vessel along with your print and allow the vapors to dissolve the layer lines. This, of course, is both highly toxic and flammable, but it can be effective if you time everything exactly right.

There are also commercial smoothing devices like the Polymaker Polysher, which use aerosolized isopropyl alcohol to dissolve layer lines from the company’s custom Polysmooth filament. While somewhat safer than acetone vapor smoothing, the process is still a bit hit or miss in terms of results.

Selective shine

What none of these techniques can produce, however, is selective shine. Objects in the real world aren’t just shiny or not shiny. Take your smartphone, for example. The screen is very shiny, but the sides of the phone are less so. My Apple Watch screen has a high sheen to it, but the band I’m wearing is flat black.

Also: Everything you need to know about 3D printing and its impact on your business

Regular 3D printers, on their own, can’t produce that level of sheen distinction. Sure, if you’re an artist, you could paint parts of the print with a glossy paint and other parts with a matte paint, but out of the machine, you’re quite limited.

Until now.

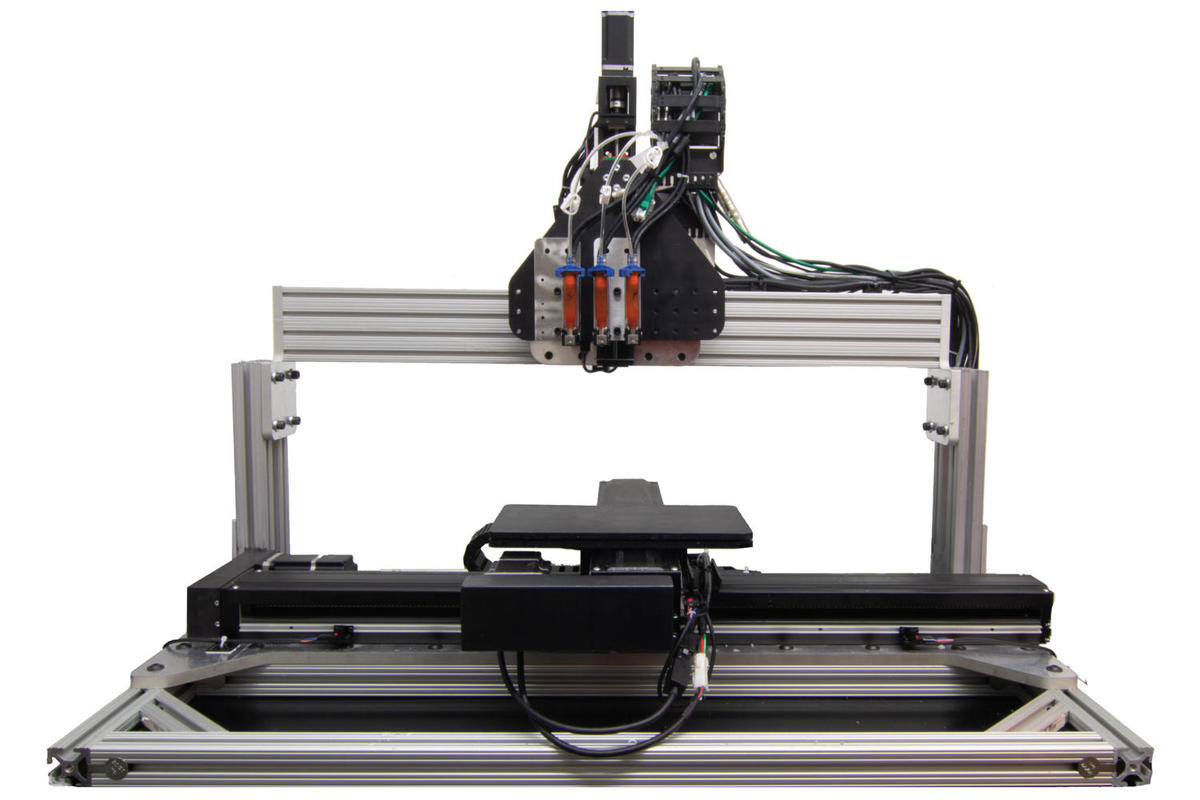

MIT: “This image shows the new 3D printer the researchers designed. The hardware includes large nozzles with variable pressure and open/closing rates, which allow the printer to adjust to different varnish viscosities. The system also includes software algorithms that create a customized halftoning pattern, comprising a mix of varnishes that reproduces the desired gloss pattern.”

Image courtesy of the researchers

Researchers Micheal Foshey, a mechanical engineer in the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL), Michal Piovarči of the University of Lugano in Switzerland, Wojciech Matusik of MIT, Vahid Babaei of the Max Planck Institute, Szymon Rusinkiewicz of Princeton University, and Piotr Didyk of the University of Lugano have produced a 3D printer prototype that deposits varnish in a halftone pattern to control gloss.

According to MIT:

They designed a printer with large nozzles and the ability to deposit varnish droplets of varying sizes. The varnish is stored in the printer’s pressurized reservoir, and a needle valve opens and closes to release varnish droplets onto the printing surface. A variety of droplet sizes is achieved by controlling factors like the reservoir pressure and the speed of the needle valve’s movements. The more varnish released, the larger the droplet deposited. The same goes for the speed of the droplet’s release. “The faster it goes, the more it spreads out once it impacts the surface,” says Foshey. “So we essentially vary all these parameters to get the droplet size we want.”

Varnish is applied in a pattern that fools the eye into seeing the appropriate sheen:

Discrete varnish droplets are arranged in patterns that, when viewed from a distance, appear like a continuous surface. “Our eyes actually do the mixing itself,” says Foshey. The printer uses just three off-the-shelf varnishes – one glossy, one matte, and one in between. By incorporating these varnishes into its preprogrammed halftoning pattern, the printer can yield continuous, spatially varying shades of glossiness across the printing surface.

Right now, the project is limited to producing bas relief objects (flat objects with 3D dimensionality), but they hope to expand the system to support traditional 3D printers. According to University of Lugano’s Piotr Didyk “the system is designed in such a way that the future integration with commercial 3D printers is possible.”

Cool.

You can follow my day-to-day project updates on social media. Be sure to follow me on Twitter at @DavidGewirtz, on Facebook at Facebook.com/DavidGewirtz, on Instagram at Instagram.com/DavidGewirtz, and on YouTube at YouTube.com/DavidGewirtzTV.