A research team led by Dr. Ji-Hoon Lee of the Department of Hydrogen Energy Materials at the Korea Institute of Materials Science (KIMS) developed a three-dimensional, porous, carbon-based current collector material and applied it to secondary batteries and supercapacitors to improve energy density and lifespan at the same time. The researched conducted with Prof. Insuk Choi at Seoul National University and Prof. Jungho Shin at Gangneung-Wonju National University was published as a cover paper on May 18 in ACS Applied Materials & Interfaces.

A current collector acts as a crucial part of manufacturing a thin film electrode plate. However, since the current collector occupies a significant portion of the weight and size of the electrode, it is limited in improving the energy density and reducing the weight and volume of the energy storage device.

This characteristic is particularly prominent in fields where medium and large-sized electrochemical energy storage devices are applied, such as electric vehicles, and even in repeated charging and discharging. In addition, the cause of shortening the life of the battery is the delamination of the active material or the corrosion of the existing metal current collector due to the inflow of moisture and air into the battery.

The researchers fabricated a carbon-based current collector with a three-dimensional porous carbon structure, which is stable in various environments, by utilizing a floating catalyst chemical vapor deposition (FC-CVD) method. Next, they succeeded in fabricating electrodes by applying the active material coating process conventionally used in the secondary battery industry to facilitate the mass production process. Through this approach, the research team overcame the existing constraints of modifying current collector materials according to the specific operating environment, such as electrolyte and operating voltage.

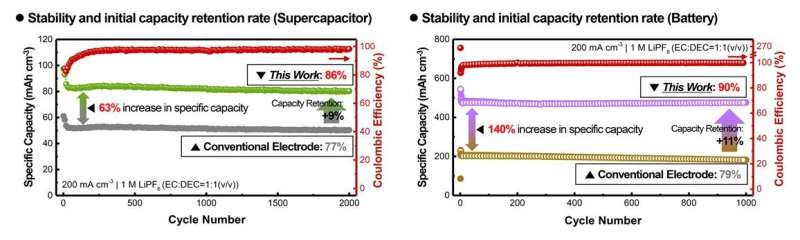

Life stability and initial capacity retention rate improvement by current collector developed by the research team. © Korea Institute of Materials Science (KIMS)

In addition, the research team succeeded in improving energy/power density and enhanced cycling stability through wide pores of current collectors by making the porous structure facilitate the transport of lithium ions. Conventional metal foils have a limited interfacial contact area with an active material because they have a two-dimensional structure. However, the newly developed three-dimensional carbon-based current collector maximized the highly stable interfacial area and played a key role in improving the life cycle of a device.

Dr. Ji-Hoon Lee, the senior researcher, said, “As the fundamental problems of the material are solved, commercialization of the carbon-based current collector will be facilitated and the utilization of the current collector will be increased so that it will be possible to cover any scale of the energy storage devices. This study newly defined the role of the current collector, which had been limited to a minor component for electrode formation. Through follow-up research, we will strive to lead to the development of energy conversion technology that is eco-friendly and highly economical.”

More information:

Jong Han Jun et al, Intertwined CNT Assemblies as an All-Around Current Collector for Volume-Efficient Lithium-Ion Hybrid Capacitors, ACS Applied Materials & Interfaces (2023). DOI: 10.1021/acsami.3c02492

Provided by

National Research Council of Science & Technology

Citation:

Team develops a current collector for energy storage devices with high-efficiency and long cycling life (2023, June 21)