Because the sun does not shine at night but all our screens do, we need energy storage to shift solar energy production during the day to when it is needed in the evening. To cope with this intermittence of renewables, we cannot rely on wind production, which is not constant either; therefore, thousands of shipping-container-sized lithium-ion batteries have been installed in power grids around the world.

The California Independent System Operator CAISO has seen great success with their battery system. During a heat wave last September, their batteries provided 3.3 GW or 6.8% of the total power supply when demand peaked as everybody cranked up the AC after work. This helped stabilize the grid and prevented blackouts in the renewable-heavy California grid.

Where do we put all those batteries?

Grid-scale battery energy storage systems (BESS) are often deployed in rural areas, often close to massive solar farms where land cost is a small component of the budget and safety risks can easily be mitigated. However, large BESS will have to be deployed in densely populated areas as well. The temporal mismatch between production and demand is clear, but the fact that there is also a locational mismatch is less well known.

Demand is not homogenous throughout the entire grid, and if the cheapest energy can not freely flow to where it is needed, congestion tariffs cause spikes in energy cost. BESS near strategic grid nodes can thus help manage congestion without incurring the cost of having to build new and very expensive transmission lines.

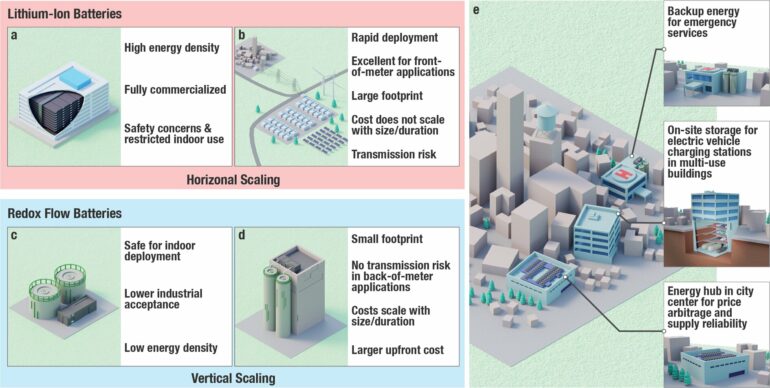

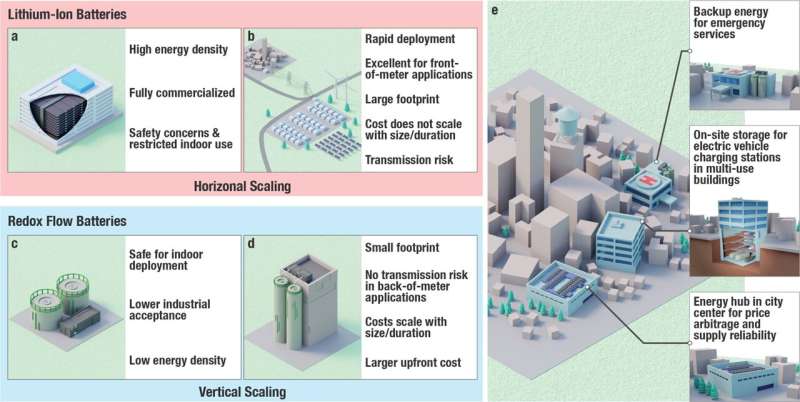

Here, the battery chemistry becomes highly relevant because safety and footprint are crucial design considerations, for example, in residential areas. If you install several megawatts worth of batteries in a residential neighborhood, they better be safe.

Lithium-ion batteries are very safe to operate, with reported cell failures of less than 1 in 10 million. At megawatt scale, however, the risk increases as there are around 150,000 individual batteries in each BESS unit. In contrast to the really low cell failure rate, the lithium-ion BESS unit failure rate is closer to 1 in 1,000. Here, failure means overheating, fires, toxic gases, and in the worst case, explosions.

Schematic comparison of battery energy storage systems using lithium-ion or flow batteries. (a) Lithium-ion BESS on cell and unit level have high energy density but cannot be employed indoors. (b) Horizontally scaled lithium-ion BESS cannot be deployed at scale in urban areas. (c) Flow batteries have lower energy density on unit level but can be installed in buildings due to inherent non-flammability. (d) Vertical scaling of flow batteries translates into highly effective land-use. (e) Vertically scaled flow batteries allow the deployment of small footprint energy hubs in city centers for supply security, emergency backup power for critical infrastructure like hospitals, or on-site storage for electric vehicle charging stations that are integrated in parking infrastructure. © Energy Advances (2023). DOI: 10.1039/D3YA00208J

Water-based electrolytes

A key issue is the flammable electrolyte that is employed in state-of-the-art lithium-ion batteries. A promising approach for large-scale applications is to use water-based electrolytes that are inherently nonflammable instead. “There is a plethora of aqueous battery chemistries and architectures out there, but they all come with a fraction of the energy density that lithium-ion batteries can offer,” says the team.

Redox flow batteries, for example, are a promising technology for grid-scale storage as they are highly scalable. Instead of storing energy in solid electrodes, flow batteries use liquid electrolytes that are pumped through an electrochemical cell to provide power. These electrolytes are nonflammable as they are water-based, making flow batteries inherently safe to operate. But low energy density is commonly cited as a major limitation of the technology.

Does it matter?

For flow batteries, energy density is closely linked to the solubility of active materials. I worked on improving solubilities of active materials for two years, and it’s quite challenging. I wondered, if we can build tall electrolyte tanks or stack battery containers on top of each other since the chemistry is very safe, how important can cell-level energy density be for large installations?

I took to Google Earth and tracked down megawatt-scale BESS around the globe. “Using satellite images, I measured the footprint of the installations. I found that the energy capacity per area, or kilowatt hours per square meter, is in many cases comparable between lithium-ion and flow batteries. But on cell level, it differs by an order of magnitude.

This unlinking of BESS footprint from cell-level energy density in grid-scale installations highlights that this metric is rather unimportant for this application. For other use cases, for example, home batteries, it’s a different story.

Eventually it comes down to cost. What our data really shows is that current aqueous chemistries have sufficiently high energy densities and that we need to focus more on aspects such as lifetime, scalability, automated manufacturability, recyclability and supply chain safety, without discarding any one technology based on the somewhat hyped metric of energy density.

Conclusion

Counterintuitively, water-based batteries could be excellent contenders for applications where BESS need to be vertically scaled due to limited land availability. Inherently nonflammable systems can be deployed in densely populated areas or even within multi-use buildings. This opens doors that remain locked to state-of-the-art lithium-ion BESS.

There is no one-size-fits-all battery technology that is perfect for every possible use case, but the time for safety-focused, megawatt-scale solutions is clearly here, and research efforts need to focus more on cost, lifetime and manufacturability, rather than energy density.

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about ScienceX Dialog and how to participate.

More information:

David Reber et al, Beyond energy density: flow battery design driven by safety and location, Energy Advances (2023). DOI: 10.1039/D3YA00208J

Bio: David Reber is an SNSF Ambizione group leader at the Swiss Federal Laboratories for Materials Science and Technology (Empa). Prior to his current position, Dr. Reber was a Postdoctoral Associate in Prof. Michael Marshak’s group at the University of Colorado Boulder. Guided by Prof. Corsin Battaglia and Prof. Frank Nüesch, he received his PhD from the École Polytechnique Fédérale de Lausanne (EPFL) in 2020.

Citation:

The role of energy density for grid-scale batteries (2023, August 4)