Hydrogen is a promising energy source due to its high energy density and zero carbon emissions, making it a key element in the shift toward carbon neutrality. Traditional hydrogen production methods, like coal gasification and steam methane reforming, release carbon dioxide, undermining environmental goals. Electrochemical water splitting, which yields only hydrogen and oxygen, presents a cleaner alternative.

While proton exchange membrane (PEM) and alkaline water electrolyzers (AWEs) are available, they face limitations in either cost or efficiency. PEM electrolyzers, for instance, rely on costly platinum group metals (PGMs) as catalysts, whereas AWEs often operate at lower current densities and efficiencies.

Anion exchange membrane water electrolyzers (AEMWEs) combine the benefits of both PEM and AWEs, using low-cost, non-PGM catalysts while supporting higher current densities and energy conversion efficiencies. However, AEMs face technical challenges, especially degradation under alkaline conditions, which impacts long-term stability. Advances in AEM materials, particularly those enhancing chemical durability, conductivity, and mechanical strength, are critical to overcoming these challenges.

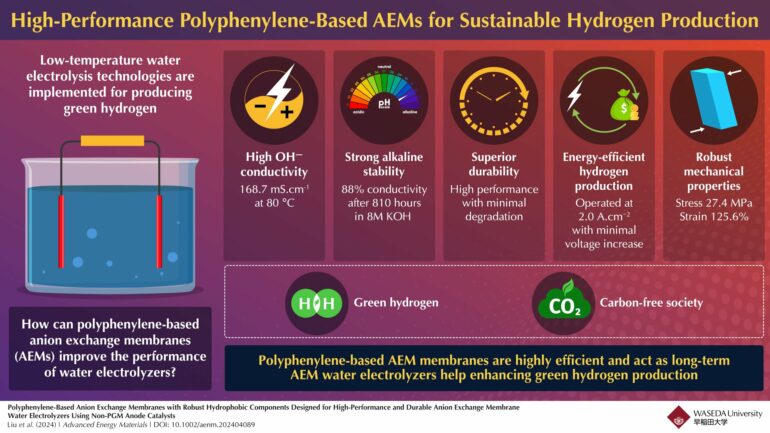

To address these issues, Professor Kenji Miyatake from Waseda University, Japan, working alongside researchers at the University of Yamanashi, developed a new anion exchange membrane (AEM) with durable hydrophobic components. High hydroxide ion (OH–) conductivity, which is essential for excellent performance in AEM water electrolyzers (AEMWEs), is another feature of this membrane, which is made to withstand extreme alkaline conditions.

Miyatake stated, “The polymer-based membrane used in this study satisfies the fundamental requirement for robust, effective materials in the production of green hydrogen to be used in water electrolysis.” The study is published in the journal Advanced Energy Materials.

The incorporation of 3,3″-dichloro-2′,5′-bis(trifluoromethyl)-1,1′:4′,1″-terphenyl (TFP) monomers into the polyphenylene backbone of the membrane is a crucial aspect of this breakthrough. Since its composition enhances stability, it possesses the capacity to endure more than 810 hours of exposure to high concentrations of potassium hydroxide at 80°C, which shows its durability in industrial applications.

The membrane demonstrated consistent performance during water electrolyzer testing, sustaining a constant current density of 1.0 A·cm-2 for more than 1,000 hours with minimal voltage change. According to Miyatake, “The durability shown here is an encouraging sign that our membrane can help reduce costs in hydrogen production.”

Further, the membrane’s OH– conductivity reached 168.7 mS·cm-1 at 80°C, surpassing the values mentioned in earlier research studies. This high conductivity is critical for achieving high current densities needed to make hydrogen production efficient. By combining durability with such high conductivity, the team believes this material design marks an important advance toward scalable and affordable hydrogen production.

With a tensile strength of 27.4 MPa and an elongation capacity of 125.6%, the membranes offer strong resilience, beneficial for stable performance over time. The durability and efficiency of these AEMs make them a valuable component in sustainable hydrogen production, supporting carbon-neutral energy initiatives. These results hold promise for applications involving green hydrogen.

The study successfully demonstrates that polyphenylene-based AEMs with hydrophobic components significantly enhance stability and exhibit high hydroxide ion conductivity with superior alkaline stability, minimizing degradation even in challenging environments. The membrane enables stable performance over prolonged operation at high current densities, marking it as an efficient, cost-effective option for green hydrogen production in AEM water electrolyzers.

More information:

Fanghua Liu et al, Polyphenylene‐Based Anion Exchange Membranes with Robust Hydrophobic Components Designed for High‐Performance and Durable Anion Exchange Membrane Water Electrolyzers Using Non‐PGM Anode Catalysts, Advanced Energy Materials (2024). DOI: 10.1002/aenm.202404089

Citation:

Transforming anion exchange membranes in water electrolysis for green hydrogen production (2024, November 14)