Electronic tattoos can have applications during health and movement sensing on human skin. Nevertheless, the existing versions are nonconformal, sticky and multi-layered. In a new report, Lixue Tang and a research team in biomedical engineering and nanoscience in China achieved the multilayer integration of an 800 percent stretchable, conformal and sticky electronic tattoo. The construct allowed the crease amplification effect, which amplified the output signal of the integrated sensors by three times. The team showed the possibility of transferring the tattoo to a different surface to formed a firm attachment without solvent or heat. The researchers used a straightforward method to fabricate the tattoo based on a layer-by-layer strategy with two materials used to fabricate the circuit mode within the tattoo. The three-layered tattoo integrated one heater and 15 strain sensors for temperature adjustment to monitor movement and to remotely control robots.

Wearable devices

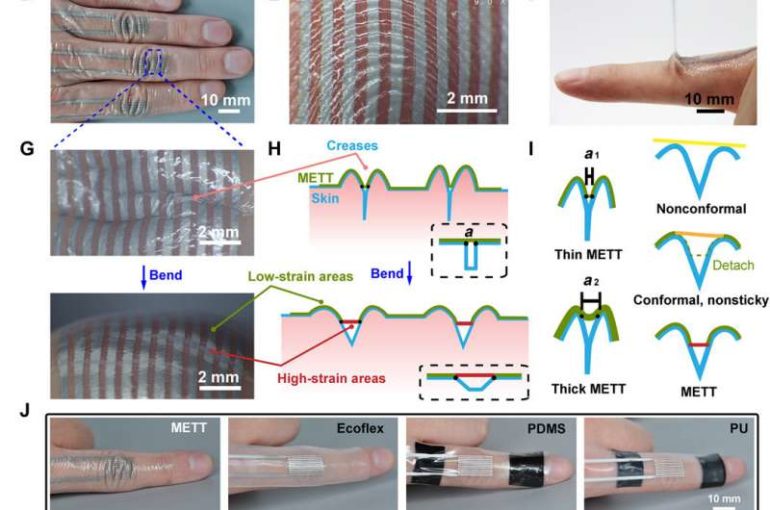

Wearable or implantable devices can seamlessly integrate with human tissues to improve the quality of life during real-time health monitoring applications. Most wearable devices are made of soft silicon substrates and are compatible with human tissues including skin, brain and heart. The materials are also chemically inert without causing damage to human tissues; however, they cannot form firm attachments to human skin to achieve stability. Current electronic tattoos can therefore be directly printed as electronic circuits on the skin or as commercial transfer tattoos. Such single-layered strategies cannot achieve circuits with multiple functions due to the inevitable overlap with complex circuits. To balance existing incompatibilities, Tang et al. developed a multilayer electronic transfer tattoo (METT), which they embedded into small features including finger creases and fingerprints on the skin for firm attachment during repeated deformations.

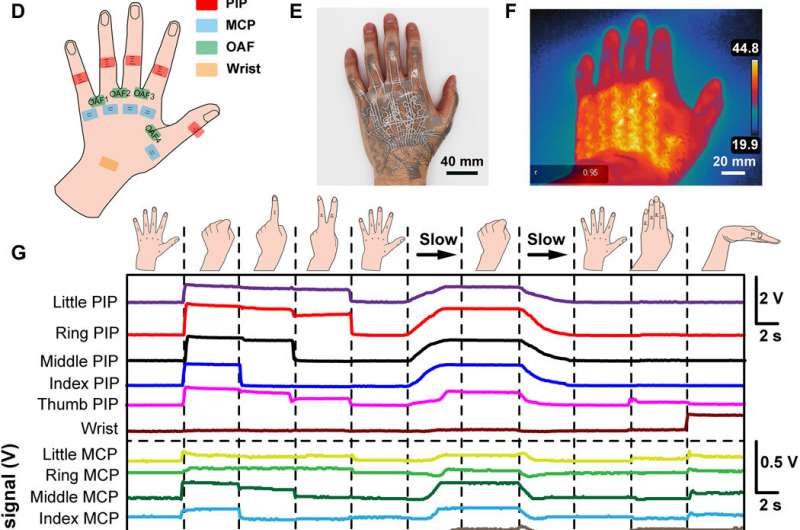

The conformal and sticky structure of the METT allowed crease amplification effects; where the strain focused on the crease of the skin, leading to the amplification of the output signal of the strain sensors on the tattoo. The tattoo showed excellent stretchability and repeatability. As a result, large local deformations caused by crease amplification did not cause degradation of the strain sensors or of the interconnects made of metal-polymer conductors (MPC). The researchers pushed the limit of the liquid metal-based electronic tattoo allowing the integration of any number of strain sensors or other functional components, and integrated 15 strain sensors and one heater in an attempt hitherto impossible for single-layered electronic tattoos. Using the METT, the team demonstrated a remotely controlled robot hand.

Developing the multi-layered electronic transfer tattoo (METT)

The METT contained three parts including an adhesive layer, a release layer and circuit modules between the two. When Tang et al. applied pressure, the adhesive layer allowed the METT to form tight and conformal attachment to the skin. The circuit layer maintained a thin poly(styrene-butadiene-styrene) (SBS) film with stretchable conductors embedded therein. The circuit module within the three-layered METT made of the metal-polymer conductors contained three circuit-layers with strain sensors and one heater on the third circuit layer. The MPC provided excellent conductivity and stretchability to the device, while the SBS film supported the conductors and electrically isolated them in different layers. When Tang et al. attached the tattoo to the skin via pressure and removed the release layer, the circuit modules of the METT transported onto the skin for firm attachment.

The METT fabrication strategy

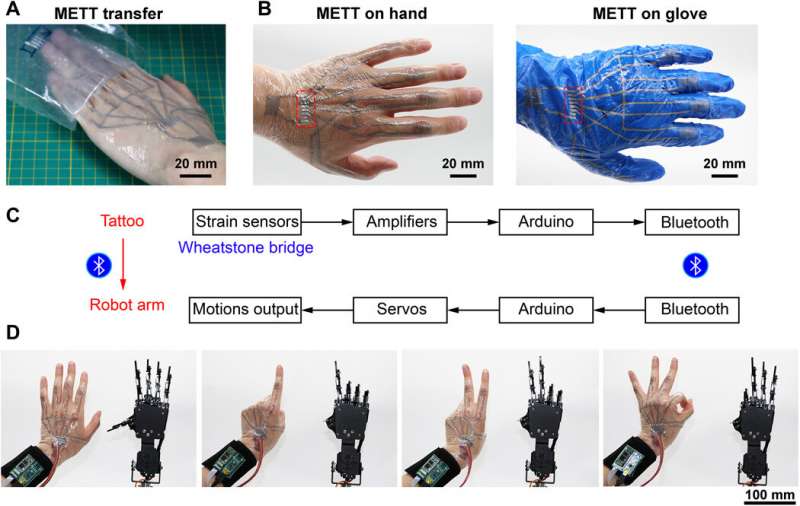

The team created a layer-by-layer fabrication strategy to create the METT, starting from the outermost layer to the tattoo on the skin. They then directly printed the metal polymer conductors (MPC) on to the SBS (poly(styrene-butadiene-styrene) film and formed a vertical electrical connection with other layers to increase the number of circuit layers. The MPC was not conductive after printing at first due to the nonconductive oxide layer on the liquid metal particles; however, surface stretching broke the surface to generate conductive paths. The METT firmly attached to the skin after applying pressure and a soft and thin circuit module remained on the skin. The three-layered construct could monitor 15 degrees of freedom of the hand to transfer the dexterity of the human hand to a robotic hand with similar degrees of freedom.

Testing the electromechanical performance of the device

The team then tested the electromechanical performance of the metal polymer conductor-based strain sensors in the METT. The resistance of the material increased with increasing tensile strain and facilitated easy stretching of up to 800%, far exceeding deformation of the skin. The sensors also showed excellent repeatability after being stretched for 1000 cycles. Tang et al. calculated the modulus of METT to be close to the skin modules. The stretchable METT was conformal and sticky, thereby causing the crease amplification effect. This allowed the team to embed the METT into creases on the skin, such as fingerprints. The skin within creases were not completely covered by the METT; instead, it remained attached firmly within creases to ensure strains focused on the regions of interest when bending the fingers. The results allowed the focused strain to amplify notably compared to strain sensors under an average strain, highlighting the crease amplification effect. The scientists also employed pressure-sensitive adhesives to improve the crease amplification effect of the METT, where the material could remain firmly attached to the skin even during vigorous exercise.

METTs to detect hand movement

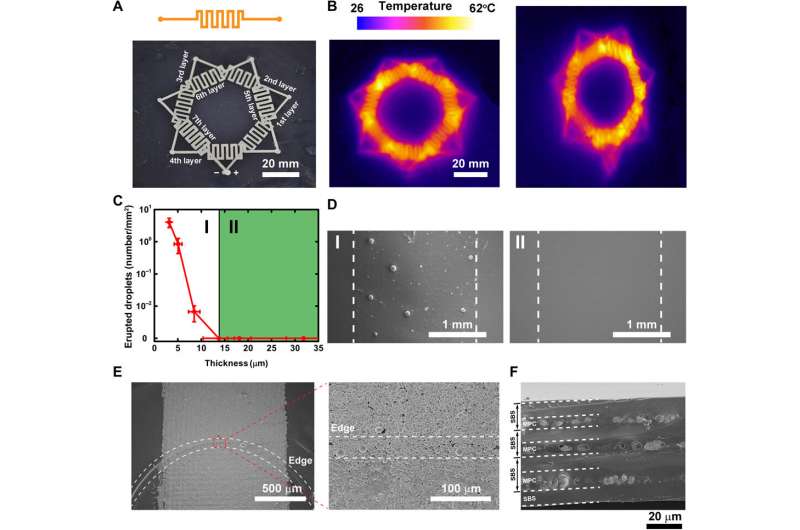

Tang et al. next demonstrated the scalability of the METT by constructing a seven-layered tattoo as a stretchable heater containing seven serpentine-shaped heaters on seven different layers connected in series to the power supply. However, the increased number of layers decreased the conformability of the tattoo. Electronic tattoos were therefore sufficient with two layers alone for most functions. Tang et al. also developed and studied the cross-section of a three-layered tattoo with liquid metal particles embedded within its architecture to form conductive networks in each layer. The researchers used the METT to measure the motions of the hand with sensors positioned on the skin and simultaneously measured the movement of the human hand in 15 degrees of freedom. Then they developed a two-layer METT to remotely control a robotic hand with 6 degrees of freedom in real time. The team amplified and transferred the signals caused by bending the fingers to the robotic hand through Bluetooth to control systems in medical research and in the military field.

In this way, Lixue Tang and colleagues attained multi-layered electronic tattoos for crease amplification. They formed a layer-by-layer fabrication strategy to form the METT with different layers while retaining the effects. Using a three-layered METT, the team measured 15 degrees of freedom of the hand and developed a strategy to perform delicate and complex tasks remotely with a robotic control system.

Ultrathin electronic tattoos for wearable computing

More information:

Tang L. et al. Multilayered electronic transfer tattoo that can enable the crease amplification effect, Science Advances, DOI: 10.1126/sciadv.abe3778

Lee S. et al. Ultrasoft electronics to monitor dynamically pulsing cardiomyocytes, Nature Nanotechnology, doi.org/10.1038/s41565-018-0331-8

Chung H. U. et al. Skin-interfaced biosensors for advanced wireless physiological monitoring in neonatal and pediatric intensive-care units. Nature Medicine, doi.org/10.1038/s41591-020-0792-9

2021 Science X Network

Citation:

Electronic transfer tattoo with a crease amplification effect (2021, January 27)

retrieved 29 January 2021

from https://techxplore.com/news/2021-01-electronic-tattoo-crease-amplification-effect.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.