A newly developed method of levitating and manipulating tiny objects using sound waves could represent a major step forward for the technology.

Engineers in Japan have figured out how to pick up objects from reflective surfaces using acoustic levitation. Although they can’t yet do so reliably, the advance could help unlock the full potential of the manipulation of physical objects using nothing but sound.

Biomedical engineering, nanotechnology and the development of pharmaceuticals are some of the fields in which manipulating objects without touching them is potentially really useful. We can already do this with a technology called optical tweezers, which use lasers to generate sufficient radiation pressure to levitate and move extremely small particles.

Acoustic tweezers – where pressure generated with sound waves can be used to move particles – have the potential to be an even more powerful tool. They could be used to manipulate a wider range of materials, and at larger sizes – up to the millimeter scale.

However, despite being first discovered in the 1980s, there are significant limitations hindering acoustic tweezers from broad practical application. To start off, you need a reliable ‘trap’ made up of sound waves.

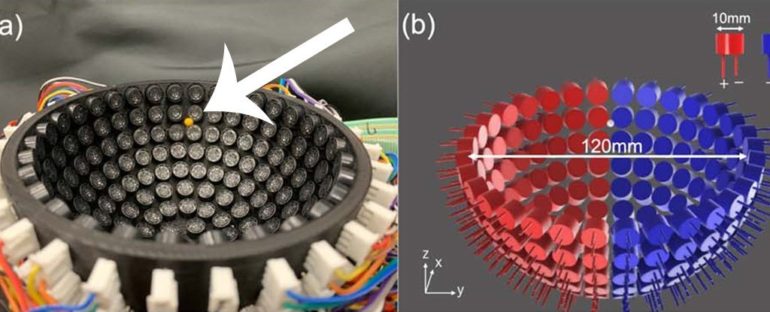

Hemispherical arrays of acoustic transducers can be used to create the sound trap, but controlling them in real-time is tricky, since you need to create just the right sound field to lift an object and move it far from the transducers.

It gets even trickier if there is a surface that reflects sound, since this can complicate the sound field.

Engineers Shota Kondo and Kan Okubo of Tokyo Metropolitan University in Japan have figured out how to build a hemispherical acoustic array that can lift a 3-millimeter polystyrene ball from a reflective surface.

“We propose a multi-channel hemispherical ultrasonic transducer array for non-contact pick-up on a rigid stage with reflection,” they wrote in their paper.

“The phase and amplitude of each channel are optimized using the sound reproduction method. This creates an acoustic trap at only the desired position, and pick up can thus be realized on the rigid stage. To the best of our knowledge, this is the first study to demonstrate non-contact pickup using this approach.”

Their technique relies on splitting the transducer array into blocks, which is more manageable than trying to control the transducers individually. Then, they used an inverse filter to reproduce sounds based on the acoustic waveform. This helps optimize the phase and amplitude of each transducer channel to produce the desired acoustic field.

Three-dimensional simulations showed how and where the field was being generated using these techniques.

This field can then be moved around, which – of course – also moves around the particle trapped therein. Using this array, the researchers were able to pick up their styrofoam from a mirrored surface, but unreliably – sometimes the ball scattered away from the acoustic pressure, rather than becoming trapped.

Nevertheless, the work represents a step forward, since contactless pickup from a reflective surface had never been done before. Doing so – even unreliably – shows us how to move forward.

“In future studies,” the researchers wrote, “the robustness of the proposed method will be improved for practical use of non-contact pick-up.”

The research has been published in the Japanese Journal of Applied Physics.