Florida Tech professor emeritus Martin Glicksman’s latest metals/materials science research has implications for the metal casting industry, but it also has a profound personal connection inspired by two late colleagues.

Glicksman’s research, “Surface Laplacian of interfacial thermochemical potential: itsrole in solid-liquid pattern formation,” was published in the November edition of Springer Nature’s partner journal Microgravity. The findings may lead to a better understanding of the solidification of metal castings, allowing for engineers to potentially make longer-lasting engines and stronger aircraft and advance additive manufacturing.

“The casting, welding, and primary metals production are all multi-billion-dollar businesses of great societal importance, when you think about steel, aluminum, copper—all important engineering materials,” Glicksman said. “You can appreciate we’re talking about materials, for which even small improvements are worth a lot.”

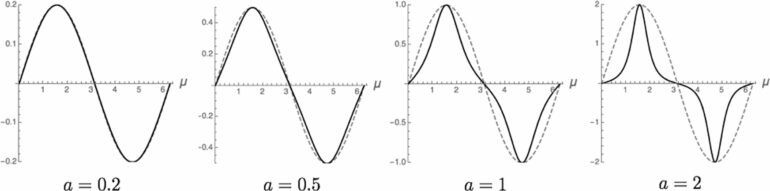

Much as crystals form when water freezes, similar things occur when a molten metal alloy is solidified to create cast products. Glicksman’s research reveals that during solidification of the metal alloy, surface tension between crystal and melt, as well as the curvature variations of crystals during growth, drives heat flow, even on stationary interfaces. This basic discovery is fundamentally different from the commonly used Stefan balances in casting theory, where the heat energy emitted from a growing crystal is proportional to its growth speed.

Glicksman noted that crystallite’s curvature reflects its chemical potential: a convex curvature slightly lowers the melting point, while a concave curvature slightly raises the melting point. That is well known from thermodynamics. What is new, and now proven, is that gradients of that curvature can induce additional heat flows during solidification that are not considered in conventional casting theories. Moreover, these heat flows are “deterministic” not stochastic, like random noise, and could, in principle, be controlled to advantage during casting processes to modify alloy microstructures and improve properties.

“When you have complicated crystalline microstructures freezing, curvature-induced heat flows occur that could be controlled,” Glicksman said. “Those heat flows in the case of a real alloy casting could, if controlled by chemical additions or physical effects, such as pressure or strong magnetic fields, improve the microstructure, which ultimately controls the chemical and mechanical properties of cast alloys, welded structures and even 3D-printed materials.”

Beyond its scientific significance, this research is of great personal importance to Glicksman largely due to late colleagues who helped support it. One of those colleagues is Paul Steen, a fluid mechanics professor at Cornell University who passed away last year. Steen had helped Glicksman with microgravity materials research years ago, utilizing space shuttle fluid mechanics and materials research. Springer Nature dedicated the November issue of Microgravity to Steen and contacted Glicksman about writing a scientific paper in his memory concerning this research.

“It spurred me on to put something together that was interesting, and that Paul would have especially appreciated. And of course, many readers looking at this research paper are also interested in areas that Paul contributed to, which is interfacial thermodynamics,” Glicksman said.

Another colleague who inspired Glicksman’s paper was Semen Koksal, a Florida Tech mathematics professor, department head and academic affairs vice president who passed away in March 2020. Glicksman described her as a kind, intelligent person who was a delight to be around, noting that she was helpful providing her mathematical expertise to his research.

“She and I were good buddies, and she was deeply interested in my work. Semen helped me when I was stuck formulating the differential equations to explain the phenomenon of curvature-induced heat flow,” Glicksman said. “We spent a lot of time discussing my equations and how to formulate them, their restrictions, and so on. She was a person I consulted with and was so helpful in formulating the mathematical theory and helping me to get it right.”

More information:

Martin E. Glicksman et al, Surface Laplacian of interfacial thermochemical potential: its role in solid-liquid pattern formation, npj Microgravity (2021). DOI: 10.1038/s41526-021-00168-2

Provided by

Florida Institute of Technology

Citation:

Breakthrough metals research has implications for the metal casting industry (2022, January 10)