A team of researchers from NYU Abu Dhabi’s Advanced Microfluidics and Microdevices Laboratory (AMMLab) have developed new kind of Atomic Force Microscopy (AFM) probes in true three-dimensional shapes they call 3DTIPs. AFM technology allows scientists to observe, measure, and manipulate samples and micro and nanoscale entities with unprecedented precision. The new 3DTIPs, which are manufactured using a single-step 3D printing process, can be utilized for a wider variety of applications—and potential observations and discoveries—than standard, more limited silicon-based probes that are considered state-of-the-art in our current time.

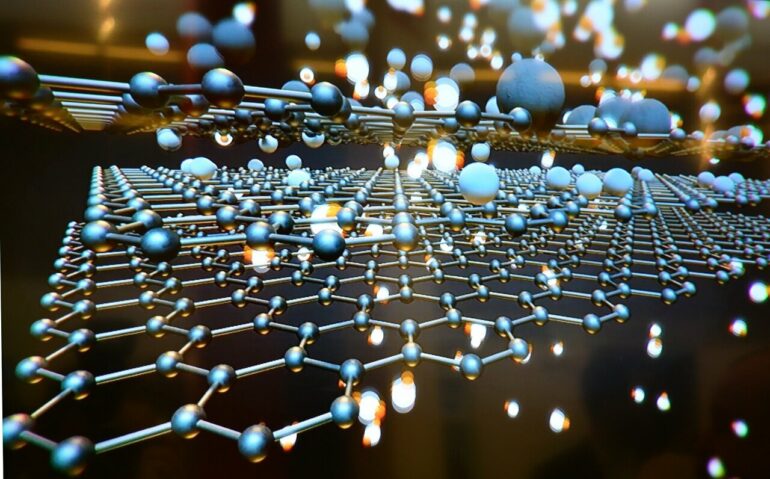

Atomic force microscopy (AFM) is a technique for characterizing samples by scanning a physical probe across surfaces, producing impressive resolutions 1,000 times higher than optical microscopy can achieve. AFM is a fundamental instrument in many disciplines including biomedical sciences, with applications ranging from characterizing viable bacteria and mammalian cells, analyzing DNA molecules, studying proteins in real time, and imaging molecules down to sub-atomic resolution.

The AFM probe, comprising a tiny cantilever beam with a miniature tip at its end, is the core of the technology. It senses and feels sample surfaces through forces of attraction and repulsion, in the same way we use our fingertips, but with a resolution down to the atomic level. Commercial AFM probes are made out of silicon, using conventional semiconductor manufacturing processes, typical in the microelectronics industry, that are limited by 2D designs and lengthy production steps. These current state-of-the-art probes are rigid, brittle, and only available in certain shapes. They are non-ideal for probing soft matter, such as mammalian cells.

In the paper published in the journal Advanced Science, the researchers present their proprietary technology for producing next generation AFM probes based on two-photon polymerization 3D printing. The resulting 3DTIPs are softer than their silicon-based counterparts, which makes them more suitable for AFM applications involving gentler interactions with cells, proteins, and DNA molecules. Importantly, the material properties of 3DTIPs make it possible to achieve scans that are more than 100 times faster than regular silicon probes of similar dimensions. Therefore, 3DTIPs might open the door for acquiring videos that capture bioactivities of proteins, DNA and even smaller molecules in real time.

“We have developed a novel technology for next-generation AFM probes with new materials, improved designs and production processes, novel shapes in 3D, and customized prototyping for a seamless production cycle for application-focused AFM probes,” said Mohammad Qasaimeh, the principal investigator of the project and Associate Professor of Mechanical Engineering and Bioengineering at NYUAD. “The ability to generate customized AFM probes with innovative 3D designs in a single step provides endless multidisciplinary research opportunities.”

“Our 3DTIPs are capable of obtaining high-resolution, high-speed AFM imaging using common AFM modes, and under air and liquid environments,” said Dr. Ayoub Glia, the first author of the study and postdoctoral associate at the AMMLab. “Refining the tip end of the 3DTIPs by focused ion beam etching and carbon nanotube inclusion substantially extends their functionality in high-resolution AFM imaging, reaching angstrom scales.”

The authors of the study hope that the multifunctional capabilities of the 3DTIPs could bring next-generation AFM tips to routine and advanced AFM applications and expand the fields of high-speed AFM imaging and biological force measurements.

More information:

Ayoub Glia et al, 3D Generation of Multipurpose Atomic Force Microscopy Tips, Advanced Science (2022). DOI: 10.1002/advs.202201489

Provided by

New York University

Citation:

Researchers develop novel 3D atomic force microscopy probes (2022, July 26)