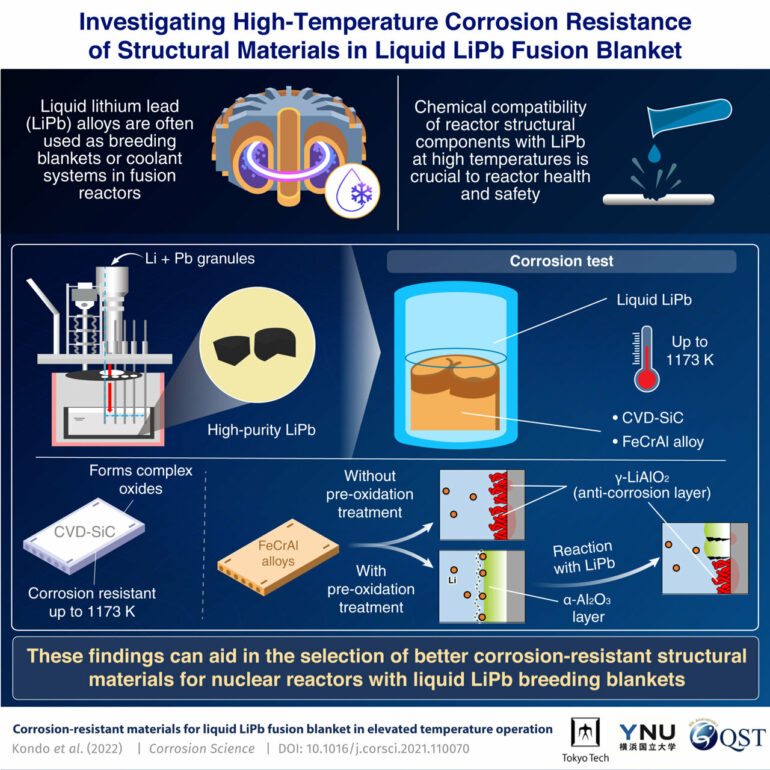

Do two promising structural materials corrode at very high temperatures when in contact with “liquid metal fuel breeders” in fusion reactors? Researchers of Tokyo Institute of Technology (Tokyo Tech), National Institutes for Quantum Science and Technology (QST), and Yokohama National University (YNU) now have the answer. This high-temperature compatibility of reactor structural materials with the liquid breeder—a lining around the reactor core that absorbs and traps the high energy neutrons produced in the plasma inside the reactor—is key to the success of a fusion reactor design.

Fusion reactors could be a powerful means of generating clean electricity, and currently, several potential designs are being explored. In a fusion reactor, the fusion of two nuclei releases massive amounts of energy. This energy is trapped as heat in a “breeding blanket” (BB), typically a liquid lithium alloy, surrounding the reactor core. This heat is then used to run a turbine and generate electricity. The BB also has an essential function of fusion fuel breeding, creating a closed fuel cycle for the endless operation of the reactors without fuel depletion.

The operation of a BB at extremely high temperatures over 1173 K serves the attractive function of producing hydrogen from water, which is a promising technology for realizing a carbon-neutral society. This is possible because the BB heats up to over 1173 K by absorbing the energy from the fusion reaction. At such temperatures, there is the risk of structural materials in contact with the BB becoming corroded, compromising the safety and stability of the reactors. It is thus necessary to find structural materials that are chemically compatible with the BB material at these temperatures.

One type of BB currently being explored is the liquid metal BB. A promising candidate for such BBs is liquid lithium lead (LiPb) alloy. As candidates for structural materials compatible with liquid LiPb at very high temperatures, a certain silicon carbide (SiC) material, CVD-SiC, and an iron-chromium-aluminum (FeCrAl) alloy pre-oxidized in air are being explored. But information on this compatibility is lacking beyond temperatures of 973 K.

Now, a team of scientists from Tokyo Tech, QST and YNU, Japan, led by Professor Masatoshi Kondo from Tokyo Tech, have demonstrated compatibility at much higher temperatures. Their findings are published in Corrosion Science. “Our study makes clear the nuances of the corrosion resistance mechanism of CVD-SiC and FeCrAl alloys in liquid LiPb up to 1173 K,” Prof. Kondo explains.

The team first synthesized high-purity LiPb by melting and mixing granules of Li and Pb in an apparatus under vacuum conditions. They then heated the alloy to the aforementioned temperatures, at which it was liquified. Samples of CVD-SiC and two variants of the FeCrAl alloy—with and without pre-oxidation treatment to form an α-Al2O3surface layer—were placed in this liquid LiPb for 250 hours for corrosion testing. Prof. Kondo observes, “An interesting finding is that contrary to previous literature, oxidation pre-treatment to form an α-Al2O3 layer did not provide corrosion resistance beyond 1023 K.”

Cross-sections of the