When it comes to our planet’s future, we all share a collective responsibility to explore innovative solutions that reduce pollution and promote sustainable living. One such revolutionary technology that has been capturing my attention lately is the microbial fuel cell (MFC). It’s not just another energy source; it’s a game-changer that promises to transform our world for the better.

In this article, I want to take you on a journey into the world of MFCs and share my excitement about the breakthroughs we’re witnessing.

Turning pollution into power: The remarkable role of diesel soot-derived carbon nanoparticles

Imagine if we could take one of the most notorious sources of pollution, vehicle exhaust soot, and turn it into a valuable asset. That’s precisely what MFCs do in our study published in the Chemical Engineering Journal. They utilize carbon nanoparticles (CNPs), a component of soot, as an efficient electrode.

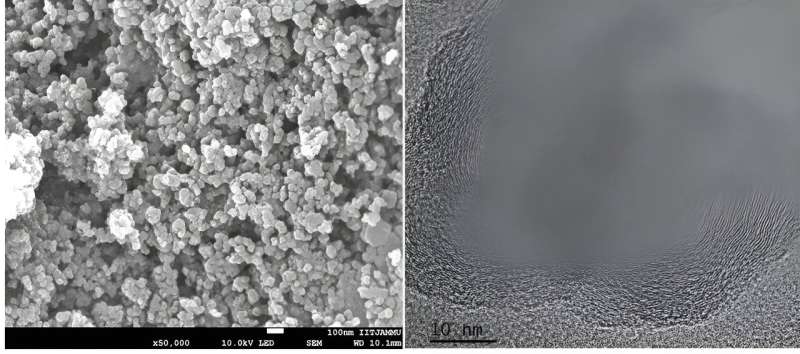

This simple act of repurposing waste not only reduces air pollution but also gives us a clean and renewable energy source. I was fascinated to learn that these CNPs have a unique nanostructure—concentric nano-onion rings. It’s like nature’s own design for efficient electricity generation. But the real magic happens when we introduce modified heteroatom-doped mesoporous fractal-like CNPs (N-S-CNPs) based electrodes (anode and cathode) into the MFC.

Micrograph of CNPs SEM (left) and HR-TEM (right) image © Dr Shiv Singh

The power of heteroatom-doped carbon: An electrocatalyst for change

Heteroatom-doped carbon, with its electron lone pairs, plays a crucial role in enhancing intrinsic and oxygen reduction catalytic activity within the MFC. This means that N-S-CNPs not only treat wastewater but also generate electricity more efficiently. The results are astounding—an open circuit voltage of 0.8 ± 0.025 V, a current density of 9,200 ± 100 mA/m2, and a maximum power density of 2,200 ± 50 mW/m2.

But what exactly makes these N-S-CNPs so special? It’s all about improving interconnected mass transfer channels, expanding the electroactive surface area, increasing hydrophilicity, and enhancing graphitization. These elements contribute to an impressive ~70% reduction in chemical oxygen demand (COD).

Nature’s collaborators: Unlocking the power of bacteria and thick biofilm

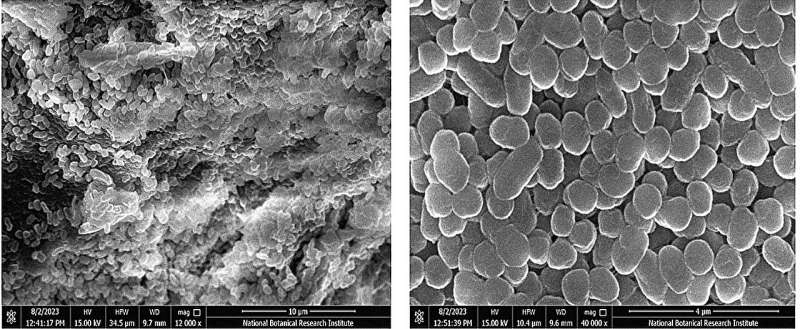

Now, let’s talk about the unsung heroes of MFCs—bacteria. Through 16s rRNA sequencing, scientists have discovered five distinct species of bacteria in local sewage water working in harmony within the biofilm. Among them, Serratia marcescens and Raoultella ornithinolytica deserve special mention for their role in forming a robust biofilm.

The cytochrome oxidase test confirms that Pseudomonas aeruginosa is a star player, facilitating rapid electron transport. One of the most exciting revelations is how the thick biofilm on the anode surface piles up a large number of electrons. This is the secret behind the MFC’s superior performance.

The rapid biofilm growth, driven by Raoultella ornithinolytica and Serratia marcescens, ensures efficient substrate conversion. But it doesn’t stop there. The heteroatoms—N, S, and O—deserve credit for boosting hydrophilicity and electroactive surface area. These elements also encourage the biofilm’s adherence and stability. Moreover, the introduction of sulfur species accelerates the oxygen reduction reaction, making it more efficient.

It’s like a microbial orchestra, where each member has a vital role to play, turning waste into power. This symbiotic relationship between bacteria and N-S-CNPs is at the heart of MFC efficiency

SEM images of Serratia marcescens (left) and Raoultella ornithinolytica (right) found in the biofilm of anode. © Dr Aradhna Mishra

The power of electronegativity

When it comes to accepting electrons, N, S, and O outshine carbon. The presence of these heteroatoms creates more active sites, increasing the opportunities for biofilm growth and ORR. Additionally, the research suggests that mass transfer significantly influences MFC performance. While it’s challenging to directly compare different MFCs due to varying designs and conditions, the data clearly shows that N-S-CNP electrodes outperform their counterparts in the literature.

A cleaner world: Wastewater treatment and beyond

Beyond energy production, these N-S-CNP electrodes have a significant role to play in wastewater treatment. Achieving a COD reduction of ~70% in just seven days demonstrates their prowess in cleaning up our waterways. As we grapple with environmental challenges, such technologies are invaluable for a cleaner world.

A glimpse into the future: Commercializing MFCs

Now that we understand the science behind it, let’s ponder the practical implications. Our study’s findings reveal a groundbreaking path forward. N-S-CNP-based electrodes are not only efficient but also cost-effective. This discovery could be a game-changer in the development and commercialization of MFCs.

Looking at the broader picture, we can’t ignore the significance of this breakthrough. Vehicle exhaust soot, once a symbol of environmental degradation, now holds the potential to power our future. The N-S-CNP-based MFCs, with their impressive performance, are a beacon of hope in our quest for sustainable energy solutions.

A bright future for N-S-CNP electrodes

In conclusion, the future looks bright for N-S-CNP-based electrodes and their applications. They have already proven their mettle as efficient electrocatalysts for various fuel cells and capacitors. But their potential extends beyond that—they can revolutionize wastewater treatment, energy production, and environmental sustainability.

As we reflect on this journey into the world of MFCs, one thing is clear—innovation is the key to a cleaner, greener tomorrow. By harnessing the power of science and technology, we can turn even the darkest of pollutants into a beacon of hope for our planet. The N-S-CNP-based MFCs are a testament to human ingenuity and our commitment to a more sustainable future. Let’s embrace these advancements and work together to create a world where cleaner energy and a healthier environment go hand in hand.

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about ScienceX Dialog and how to participate.

More information:

Yashmeen Budania et al, Multi-heteroatom doped vehicle exhaust soot derived nano-onion based economical and efficient electrodes for microbial fuel cell: A waste to wealth strategy, Chemical Engineering Journal (2023). DOI: 10.1016/j.cej.2023.145627

Bio: Dr. Shiv Singh is a distinguished scientist based at the CSIR-Advanced Materials and Process Research Institute in the vibrant city of Bhopal, India. Additionally, he serves as an Assistant Professor at the AcSIR. Dr. Singh’s academic journey has been marked by remarkable achievements, culminating in the completion of his Ph.D. in Chemical Engineering from the Indian Institute of Technology, Kanpur, a feat he accomplished between 2010 and 2015. Dr. Singh possesses a unique and invaluable skill set, specializing in the synthesis of cost-effective graphitic carbon electrode materials using chemical vapor deposition. His expertise places him at the forefront of cutting-edge research. In his current role, Dr. Singh is actively engaged in pioneering fields such as microbial fuel cells, microbial electrolysis cells, electro-bio-chemical CO2 reduction, and the development of innovative electrochemical sensors for monitoring water pollutants. His work significantly contributes to addressing critical global challenges in sustainable energy and environmental remediation.

Citation:

Harnessing the power of microbial fuel cells: A sustainable energy breakthrough (2023, October 3)