Syngas is an important feedstock for modern chemical industries and can be directly used as fuel. Carbon monoxide (CO) is its main component. Direct conversion of widespread renewable biomass resources into CO can help to achieve sustainable development.

Conventionally, bio-syngas is mainly produced through thermal-chemical processes such as pyrolysis, steam reforming or aqueous reforming, which require high temperature and consume a lot of energy.

Recently, a research team led by Prof. Wang Feng from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences, in collaboration with Prof. Wang Min from Dalian University of Technology, developed a new method to directly convert bio-polyols into CO.

The results were published in Chem on Nov. 16.

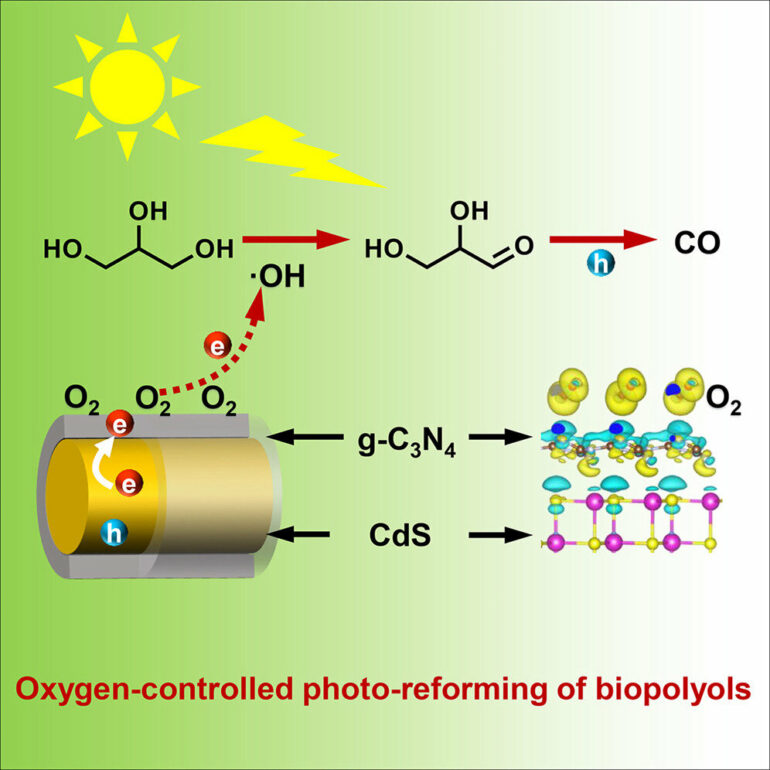

The researchers developed a photocatalytic oxidative reforming process to directly convert the bio-polyols into CO under ambient conditions, using a Z-scheme CdS@g-C3N4 catalysts with core-shell structure.

The particular catalyst structure facilitated the adsorption and activation of dioxygen on the surface of catalyst and thus promoted the production of hydroxyl radicals and enhanced the CO production rate.

They found that the regulation of the molar ratio of O2 and substrates not only accelerated the reaction rates but also prevented the over oxidation of substrates to CO2.

Under natural sunlight irradiation, this system could still stably catalyze the production of CO from glycerol.

“This work provides new ideas for the effective utilization of biomass resources,” said Prof. Wang.

More information:

Hongru Zhou et al, Oxygen-controlled photo-reforming of biopolyols to CO over Z-scheme CdS@g-C3N4, Chem (2021). DOI: 10.1016/j.chempr.2021.10.021

Provided by

Chinese Academy of Sciences

Citation:

New method converts bio-polyols into carbon monoxide (2021, November 17)