People have been using flat, ribbonlike materials, such as reed strips, to make woven baskets for thousands of years. This weaving method has reemerged as a technique for engineers to create textile and fabric structures with complex geometry. While beautiful and intricate, these baskets can also be surprisingly strong.

We are a team of structures and materials scientists at the University of Michigan. We wanted to figure out how basketlike structures that use traditional weaving techniques can be so sturdy, load-bearing and resilient.

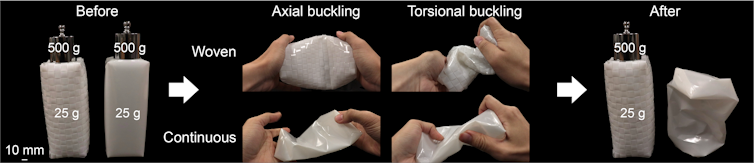

To explore the resilience of baskets, we designed a series of small woven units that can be assembled into larger structures. These woven designs provide almost the same stiffness as nonwoven structures, such as plastic bins. They also do not fracture and fail when bent and twisted the way nonwoven, continuous systems (made out of a continuous sheet material) do.

Our basketlike woven structures have many potential applications, including tiny robots that are very damage resilient – these robots can be run over by a car and still do not fail. We could also make woven clothes to help protect people from severe impacts such as car crashes. We made these woven structures using Mylar (a type of polymer material), wood and steel.

Basket weaving as a practice has been around for centuries.

Mlenny/iStock via Getty Images

Testing woven baskets

Early humans made baskets by weaving slender strips of bark or reeds, and some Indigenous societies use these techniques today. Basket weaving was an efficient way to turn one-dimensional strips into three-dimensional containers.

This geometric benefit is a direct motivation for basket weaving, but in our study published in August 2025 in Physical Review Research, we wanted to find out whether basket weaving can provide more than aesthetic value in modern science and engineering.

In our experiment, we compared woven and nonwoven containers that had the same overall shape and were fabricated using the same amount and type of materials.

The “ribbons” we used were 10 millimeters wide and two-tenths of a millimeter thick. They were always woven in the same over/under/over/under pattern. We wove baskets from the flat ribbons and then created models using 3D scans of these woven containers that helped us examine the underlying similarities and differences between the woven and continuous structures.

We found that these containers had similar stiffness to containers not made from woven materials, and they also went back to their initial shape after we bent or twisted them.