Materials scientists and bioengineers at the intersection of regenerative medicine and bioinspired materials seek to develop shape-programmable artificial muscles with self-sensing capabilities for applications in medicine. In a new report now published on Science Advances, Haoran Liu and a team of researchers in systems and communications engineering at the Frontier Institute of Science and Technology, Jiaotong University, China, were bioinspired by the coupled behavior of muscles, bones, and nerve systems of mammals and other living organisms, to create a multifunctional artificial muscle in the lab. The construct contained polydopamine-coated liquid crystal elastomer (LCE) and low-melting point alloys (LMPA) in a concentric tube or rod. While the team adopted the outer liquid crystal-elastomer to mimic reversible contraction and recovery, they implemented the inner low-melting point alloy for deformation locking, and to detect resistance mechanics, much like bone and nerve functions, respectively. The artificial muscle demonstrated a range of performances, including regulated bending and deformation to support heavy objects and provide a direct and effective approach to design biomimetic soft devices.

Soft robotics bioinspired by the skeleton–muscle–nerve system

Scientists aim to implement biocompatibility between soft robotic elements and human beings for assisted movement and high load-bearing capacity; however, such efforts are challenging. Most traditional robots are still in use in industrial, agricultural and aerospace settings for high-precision sensor-based, load-bearing applications. Several functional soft robots contrastingly depend on materials to improve the security of human-machine interactions. Soft robots are therefore complimentary to hard robots with tremendous potential for applications. Biomimetic constructs have also provided alternative inspiration to emulate the skeleton-muscle-nerve system to facilitate agile movement, quick reaction or thinking, with a unique body shape to fit tasks and perform diverse physiological functions. In this work, Liu et al. were inspired by the fascinating idea of biomimicry to develop multifunctional artificial muscles to provide a simple approach for smart applications.

Biomimicry in the lab

During the experiments, the team imparted shape-programmable, deformation-locking and self-sensing features via liquid crystal elastomers (LCE), and low melting point alloys (LMPA) in the shape of a concentric tube or rod. While the outer elastomer provided reversible contraction and recovery, the inner alloy delivered shape loading for the functions of muscles and bones. To achieve rapid photothermal conversion under light irradiation, the team coated a thin film of polydopamine on the surface of the elastomer, and triggered contraction and bending deformation. The process allowed convenient functionality in complex and unknown environments to create shape-configurable artificial muscles with high load-bearing capacity and low power consumption for smart functionality.

The working principle

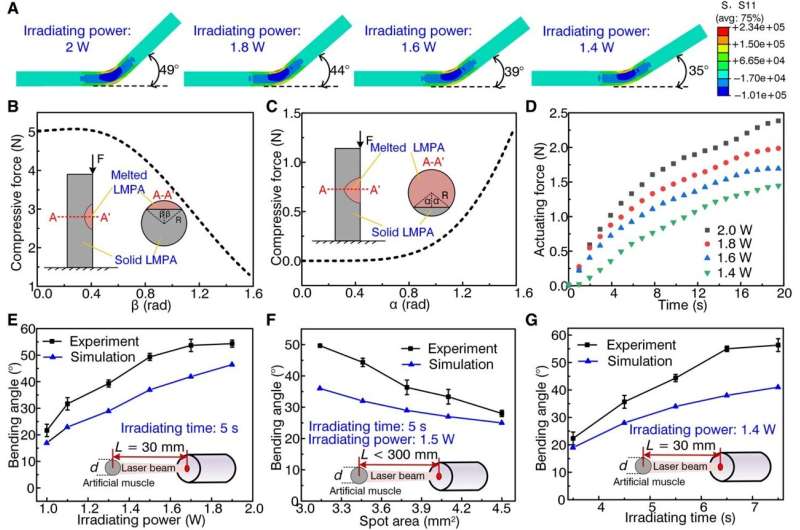

Factors affecting bending deformation of the multifunctional artificial muscle. (A) Stress distribution and bending angle of the multifunctional artificial muscle under different irradiating powers in the simulation. (B) Maximum compressive force (F) that the rod-like LMPA could bear when the laser heat locally melted a small part of the LMPA. Inset: Cross-section of LMPA. (C) Maximum compressive force (F) that the rod-like LMPA could bear when the laser heat locally melted a major part of the LMPA. Inset: Cross-section of LMPA. (D) Actuating force of the PDA-coated LCE-based tubular actuator under different irradiating powers. (E) Influence of irradiating power on the bending angle of the multifunctional artificial muscle (where L represents the irradiating distance). Inset: Illustration of laser beam applied on the surface of artificial muscle with the irradiating distance of 30 mm and irradiating time of 5 s. (F) Influence of spot area on the bending angle of the multifunctional artificial muscle (L represents the irradiating distance). Inset: Illustration of laser beam applied on the surface of artificial muscle with the irradiating power of 1.5 W and irradiating time of 5 s. (G) Influence of irradiating time on bending angle of multifunctional artificial muscle (where L represents the irradiating distance). Inset: Illustration of laser beam applied on the surface of artificial muscle with the irradiating power of 1.4 W and irradiating distance of 30 mm. In (E) to (G), three tests were conducted on samples for each data point, and the error bars present the SD of the three repeated data. © Science Advances (2022). DOI: 10.1126/sciadv.abn5722

The team showed the proposed multifunctional muscle coupled with soft elastomer and hard alloy materials. Liu et al. prepared the liquid crystal elastomers (LCE), using Michael addition reactions with amines and thiols, and created a loosely cross-linked hollow elastomer tube via gelation in a glass tube or rod. The researchers introduced the photothermal effect by developing a polydopamine layer on the material surface to maintain excellent photostability and strong absorption characteristics in the near infrared range. The team showed how the multifunctional artificial muscles could be developed by embedding pre-fabricated low melting point alloys (LMPA) into the polymer-coated LCE tube. They then irradiated the side of the artificial muscle with a laser and caused instant transformation of light into heat in the region. Comparative analysis of deformation showed instant bending about six seconds after laser irradiation, highlighting the influence of LMPA on the excellent properties of muscle deformation.

Characterizing the multifunctional artificial muscles as a reconfigurable antenna

Liu et al. performed finite element analysis using the ABAQUS software and simulated the heat source. They studied the temperature and stress distributions of the artificial muscle under diverse powers of irradiation. While large irradiating powers induced large stress in the elastomer, this further triggered a large bending angle in the artificial muscle’s alloy area. The team analyzed the bending angle of the multifunctional artificial muscle, governed by the laser power, spot area and irradiating time using experimental tests and simulations. They showed how to regulate flexible deformation in the bending angle, direction and position to increase the possibility of forming a shape-programmable artificial muscle.

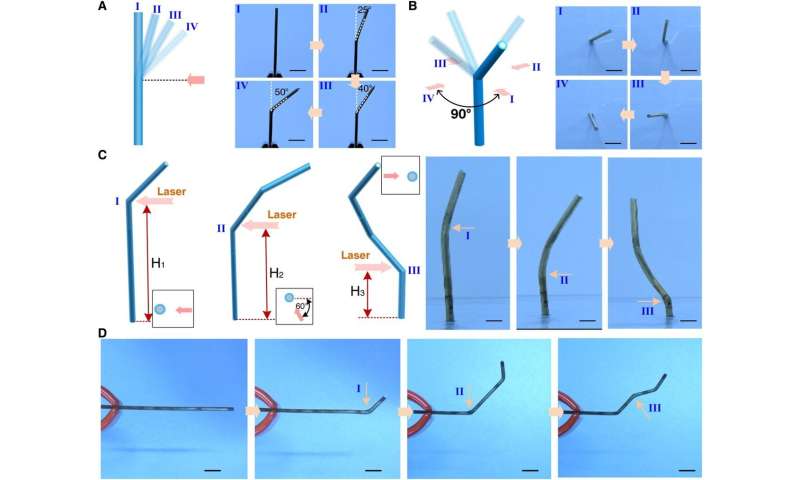

Bending deformation of a multifunctional artificial muscle. (A) Continuous adjustment of the bending angle of a multifunctional artificial muscle by irradiating the bending position from the same direction several times (I, II, III, and IV). Scale bars, 10 mm. (B) Different bending directions of the multifunctional artificial muscle obtained by adjusting the laser irradiating direction (I, II, III, and IV). Scale bars, 10 mm. (C) Multiple bending joints generated by irradiating the multifunctional artificial muscle at different positions (I, II, and III) and from different directions (0°, 60°, and 180°). Scale bars, 5 mm. (D) Shape change of the multifunctional artificial muscle by orderly applying the laser on different positions. In the experiment, one end of the multifunctional artificial muscle was clamped, and the other end was left free. Scale bars, 10 mm. © Science Advances (2022). DOI: 10.1126/sciadv.abn5722

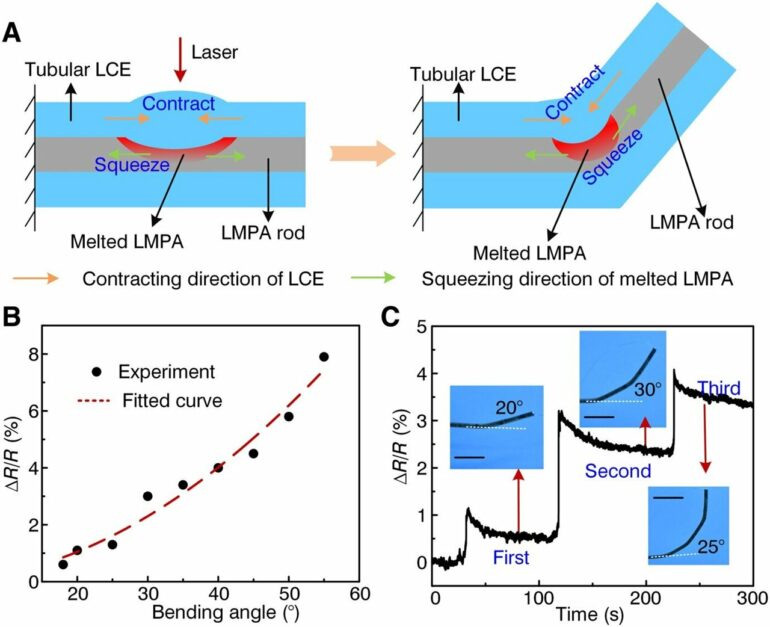

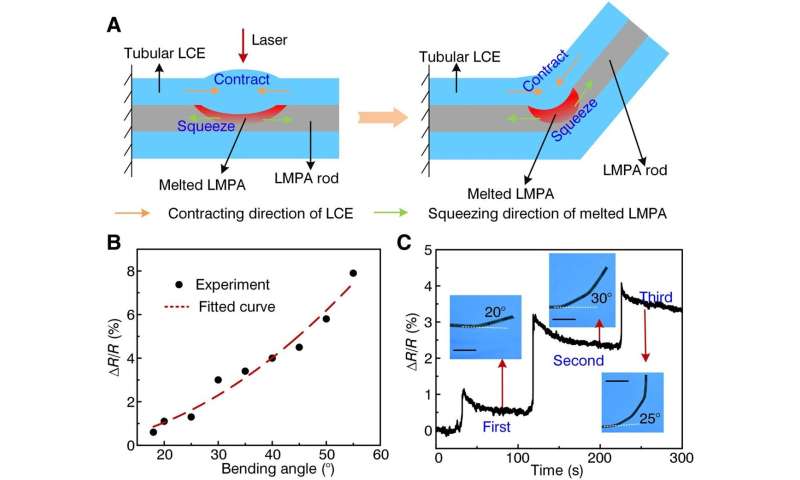

Sensing function of the multifunctional artificial muscle. (A) Schematic illustration of the multifunctional artificial muscle before and after bending deformation. (B) Response of ΔR/R to the different bending angles. Multiple samples with identical initial state in this test were irradiated under different irradiating powers. (C) Variation in resistance of one multifunctional artificial muscle sequentially irradiated at three different positions. Scale bars, 10 mm. In (B) and (C), one end of multifunctional artificial muscles was fixed, and the other end was free. © Science Advances (2022). DOI: 10.1126/sciadv.abn5722

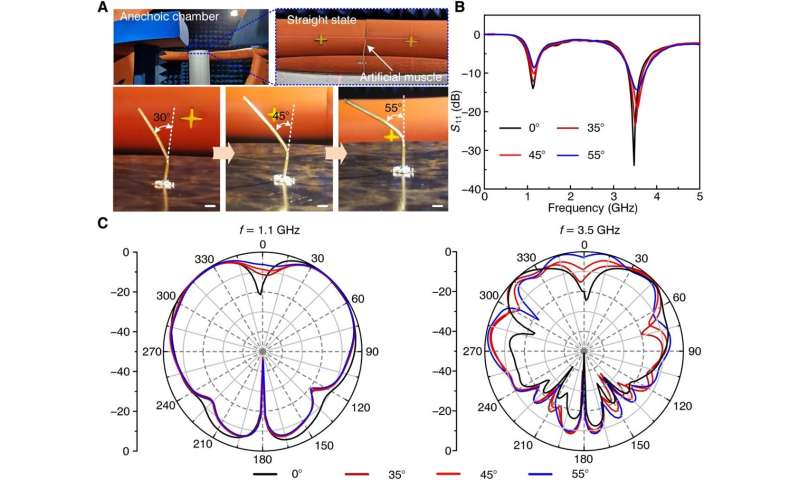

Application of the multifunctional artificial muscle as a reconfigurable antenna: (A) Different bending angles of the multifunctional artificial muscle after first, second, and third laser irradiations in anechoic chamber. Scale bars, 5 mm. (B) Experimental results of S11 band of the reconfigurable antenna at different bending angles. Agilent AV3672E-S vector network analyzer (VNA) was used for S11 measurements. (C) Vertical polarization and far-field patterns of the multifunctional artificial muscle as an antenna in the xOz plane. © Science Advances (2022). DOI: 10.1126/sciadv.abn5722

The team characterized the rapid shape transformation and deformation locking performance of the artificial muscle via a range of experiments including cyclic tests to demonstrate its deformation capacity. They further characterized the sensing functions to monitor the dynamic behavior of artificial muscles in real-time based on changes in electrical resistance. Liu et al. made further use of the multi-material properties and demonstrated applications of the proposed multifunctional artificial materials, as a reconfigurable antenna. In this instance, they measured the bending angle by applying the laser on the artificial muscle surface, to function as a remotely controlled reconfigurable antenna.

Outlook

In this way, Haoran Liu and colleagues developed a shape-programmable, deformation-locking and self-sensing artificial muscle based on the behavioral characteristics of living bones, muscles, and nerves using soft elastomer materials coupled with high-stiffness alloy materials. The rigid low melting point alloy (LMPA) mimicked the endoskeletons of living organisms, to provide structural strength, while pure soft materials made of the liquid crystal elastomer (LCE), offered powerful actuating stress and secure physical compatibility to mimic the natural muscle. The study provided a first instance, to form an artificial muscle with aforementioned features, where the constructs showed rapid shape transformation and deformation properties to yield proof-of-concept robot arms with applications across haptic displays and medicine.

More information:

Liu H. et al. Shape-programmable, deformation-locking, and self-sensing artificial muscle based on liquid crystal elastomer and low–melting point alloy, Science Advances, 10.1126/sciadv.abn5722

Hu W. et al. Small-scale soft-bodied robot with multimodal locomotion. Nature, doi: doi.org/10.1038/nature25443

Citation:

Self-sensing artificial muscle-based on liquid crystal elastomer and low-melting point alloys (2022, May 26)