Considering how quickly engineering design and manufacturing have advanced alongside computational developments, it may surprise you that very few engineers are trained in both engineering system design and artificial intelligence. There are countless opportunities for breakthrough improvements in how we develop new technology using AI in engineering design, but to succeed in these challenging areas, engineers must understand a new speciality—Design for Artificial Intelligence.

Chris McComb, Associate Professor of Mechanical Engineering at Carnegie Mellon, and his student Glen Williams, now Principal Scientist at Re:Build Manufacturing, have developed a Design for Artificial Intelligence (DfAI) framework in collaboration with researchers at Penn State University to educate and encourage the academic and industrial engineering community to adopt AI engineering design.

“Most of the time, we view AI as a tool to add onto an existing system, but to develop better systems we need to integrate AI into the engineering design process from the very beginning,” McComb explains.

A core challenge is motivating institutions to make investments in the long-term potential of AI technologies. Since engineering is product-driven and the incentives in design and manufacturing prioritizes short-term excellence, budgeting resources for long-term research and development is challenging but worthwhile.

To illustrate the importance of this, Williams described two hypothetical companies mass-manufacturing electric aircraft. For up-front development, Company A chooses a manual manufacturing path to quickly hit the market and reach profitability. On the other hand, Company B builds a data-rich process that captures intelligence throughout the lifecycle of the design. Within the next ten years, Company B is able to drastically reduce their operating cost by utilizing data-driven design that can both optimize the production of their aircraft and create better products. Company A can no longer keep up.

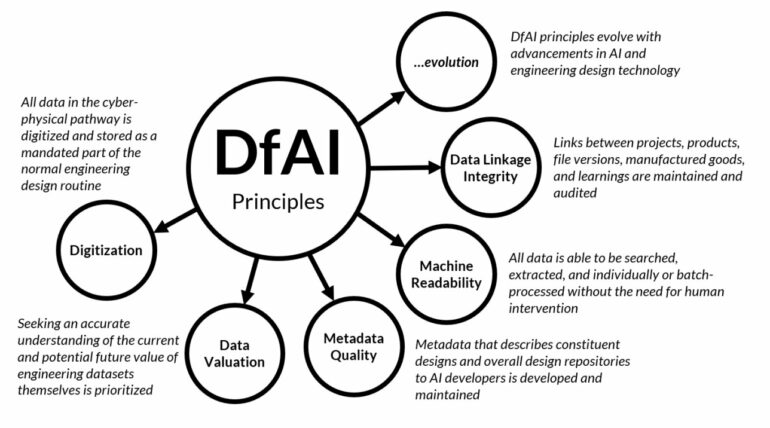

Because design and manufacturing don’t happen in silos, DfAI applies to the broader aspects of the engineering design process. Williams suggests that foundationally, advancing DfAI can be addressed through 1) raising AI literacy in industry; 2) redesigning engineering systems to better integrate with AI; and 3) enhancing the engineering AI development process.

“Engineering data is complex and not always relatable to the wider community,” McComb explains as one reason other fields may be innovating AI technology quicker. “The number of experts able to interpret this data is small, so DfAI will require individuals to have specific expertise. Academic and industry need to work together to support long-term innovation in this area.”

The team outlines three personas as necessities for DfAI: engineering designers, design repository curators, and AI developers. An engineering designer may be a person or team responsible for developing the specifications of a new project. They are the problem solvers who can understand the engineering constraints as well as the AI algorithms. Design repository curators must take the role of a database maintainer one step further by having engineering design and manufacturing knowledge to deliver design engineers the data management tools to meet workflow demands and be extensible to future demands. Finally, the AI developers must be able to ideate, develop, market and continuously improve AI software products to help the design engineers.

“We can’t think of AI development as an afterthought in our core operations,” McComb summarizes. “Unless we augment design engineers with next-generation design and manufacturing software based on deeply-integrated AI, our ability to design novel and useful technology will fall short of the potential of these new manufacturing techniques.”

Per Williams, several industries may have an easier time adopting DfAI principles. Computer science applications, such as products manufactured by digitally-driven techniques like additive manufacturing, naturally have a complex cyber-physical pathway and yield personnel that would be well-suited in adopting and driving DfAI principles. Regulated industries such as aerospace and medical devices are accustomed to following rigorous procedures and reliable data storage techniques in the context of very complex engineered systems, so they likely have the resources to begin the DfAI adoption process.

We may also see The internet of things (IoT) and smart device product designers adopting DfAI principles sooner rather than later. These designers stand to benefit not only from data during the design process, but also from vast amounts of data gathered from their devices in testing or in practice. Harnessing this valuable product data from the field could result in tremendous benefits to AI tools that help enhance the quality, performance, sustainability, and profitability of future products.

“Since there is so much variety between engineering applications, industries, technologies, and scales of operation, establishing general frameworks, common terminology, and written principles is vital to growing an interconnected community of AI Engineers that can collaborate together,” Williams elaborates. “Our DfAI framework provides the high-level starting point for these critical discussions.”

More information:

Glen Williams et al, Design for Artificial Intelligence: Proposing a Conceptual Framework Grounded in Data Wrangling, Journal of Computing and Information Science in Engineering (2022). DOI: 10.1115/1.4055854

Provided by

Carnegie Mellon University Mechanical Engineering

Citation:

DfAI: The missing piece of artificial intelligence engineering (2023, January 3)